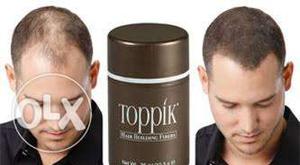

Toppik fibers

List toppik fibers

-

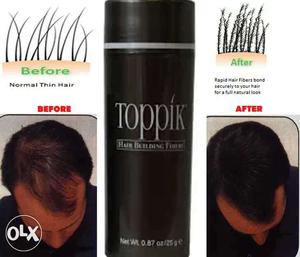

toppik fibers blend undetectably with your existing hair, instantly making it full and thicktoppik is made of all-natural coloured keratin proteindescription see a full head of hair in 30 seconds

₹ 1499

-

toppik combo- buy 3 toppik hair building fibers black, 275g + toppik fiberhold spray 118ml contact

₹ 2999

-

Caboki - toppik hair building fibers nagarjuna

₹ 1300

-

New look by caboki toppik hair fibers always it will give natural look for everyone for men and women

₹ 1300

-

Caboki toppik hair building fibers, nagarjuna

₹ 1300

-

Original toppik hair fibers drop your number to call back

₹ 1000

-

toppik hair building fibers 27s seller 2 colors black,dark brown contact5g hair loss concealer u

₹ 800

-

toppik hair building fibers available refill pack for sale call zeero

₹ 499

-

toppik bottles available in 275gm and 12gm caboki bottles available in 25gm and 9gm all colors available

₹ 999

-

Free home delivdry caboki toppik cost starting from refil pack that is 500

₹ 500

-

Caboki fibers blend undetectably with your existing hair, instantly making it full and thickcaboki is made of all-natural coloured keratin proteinsee a full head of hair in 30 seconds

₹ 1599

-

toppik & caboki instant hair buildings products available at reasonable price at all location(deliverable)

₹ 1500

-

Black sevich hair fibers bottle with box call for details

₹ 350

-

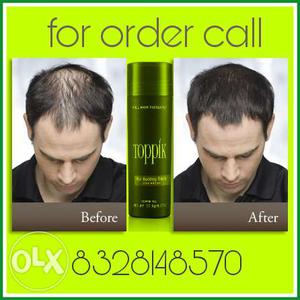

Caboki instantly eliminates the appearance of hair loss for men and women////// /////// check out the before/after pictures below submitted by people like you

₹ 1200

-

The carbon fibers are woven together to create a strong, lightweight structure, which is then infused with resin to hold the fibers togetherthe ceramic fibers are woven together to create a strong, lightweight structure, which is then infused with a ceramic matrix to hold the fibers together

ceramic matrix composite (cmc):

sicf-sic pipes (2)

sicf-sic pipes (2)

ceramic matrix composite (cmc) is a material made from ceramic fibers and a ceramic matrix

properties of carbon fiber composite (cfc):

the unique properties of cfc include its high strength, low weight, and resistance to heat, chemicals, and corrosionthe resulting material is extremely strong and lightweight, with a high strength-to-weight ratiocfc is also used in the construction of buildings and bridges, as it is strong enough to support heavy loads while remaining lightweightcarbon fiber composite (cfc) and ceramic matrix composite (cmc) are two of the most advanced materials used in engineering and manufacturing todaycfc is also resistant to heat, chemicals, and corrosion, which makes it a durable material that can withstand harsh environments

advantages of carbon fiber composite (cfc):

the main advantage of cfc is its high strength-to-weight ratioboth materials have unique properties that make them ideal for a variety of applicationsboth materials are widely used in aerospace, aviation, automotive, and energy industries, as well as in the construction of buildings and bridges

applications ceramic matrix composite (cmc):

cmc is commonly used in aerospace and aviation, as well as in the automotive and energy industriescmc is also non-magnetic and non-conductive, making it ideal for use in sensitive electronic equipmentcmc is also resistant to heat, chemicals, and corrosion, which makes it a durable material that can withstand harsh environmentsthis makes it ideal for use in high-temperature applications, such as in gas turbines and aircraft enginescmc is ideal for high-temperature applications where extreme heat resistance is required

carbon fiber composite (cfc):

carbon fiber composite pipe-tube-3d structure-cfc-cc

carbon fiber composite pipe-tube-3d structure-cfc-cc

carbon fiber composite (cfc) is a material made from carbon fiber and resin

applications of carbon fiber composite (cfc):

cfc is commonly used in aerospace and aviation, as well as in the automotive and sports industriesin this article, we will explore the properties, applications, and advantages of each material

conclusion:

in conclusion, both carbon fiber composite (cfc) and ceramic matrix composite (cmc) are advanced materials that have unique properties and advantages

related news /knowledge:

carbon carbon composite, cfc, carbon composite, c/c

carbon ceramic composite material and parts

carbon fiber reinforced silicon carbide composites (c/sic, c/c-sic)-(1)

ceramic matrix composite (cmc) material | professional manufacturer in chinaadditionally, cmc is able to withstand extremely high temperatures, making it ideal for use in high-temperature applications

properties ceramic matrix composite (cmc):

the unique properties of cmc include its high strength, low weight, and resistance to heat, chemicals, and corrosionthis makes it ideal for applications where strength and durability are important, but weight is a concernit is used to create parts such as aircraft wings, car body panels, and sporting equipment such as tennis rackets and bicycles

advantages ceramic matrix composite (cmc):

the main advantage of cmc is its ability to withstand extremely high temperaturescfc is ideal for applications where strength and durability are important, but weight is a concernit is used to create parts such as aircraft engine components, gas turbine blades, and automotive brake diskscfc is also non-magnetic and non-conductive, making it ideal for use in sensitive electronic equipmentcmc is also used in the construction of buildings and bridges, as it is strong enough to support heavy loads while remaining lightweightIndia

₹ 11

-

Utility & guest mattress - feet / 3 feet) 1'' inch thickness - good density-rool up mattress- hostel mattress, travel bed / washable / dry & breathable / no heat / recyclable / non-toxic / flame retardant / first time in india / celebrity mattress co manufacturing of fibrous cushion mattress customize mattress premium utility & guest mattress hostel mattress baby beds -you anytime anywhere sleep companion cool mattress first time in india no heat made out of millions of breathable fibers clean / safe / comfort / breathable / durable / soft / versatility adaptable & flexible during travel dry & breathable hollow fiber holds more air than fibers recyclable non -toxic flame retardant contact

₹ 1200

-

It is a high-performance composite material formed by implanting high-temperature-resistant continuous ceramic fibers into a ceramic matrixcmc material introduction

ceramic matrix composites (cmc) are a type of composite material that is composited with ceramics as a matrix and various fibersceramic matrix composites can be divided into two categories according to the continuity of the reinforcement: continuously reinforced composites and discontinuously reinforced compositesthrough the optimization of the preparation process, especially the composition and structure design of the interface layer, the mechanical properties of ceramic matrix composites have been qualitatively improved compared with single-phase ceramicscomparison of preparation processes of ceramic matrix composites

chemical vapor infiltration (cvi)

during the preparation process, the fiber damage is small, the prepared ceramic matrix has high purity and complete crystal form, and the mechanical properties of the composite material are high

high temperature resistancecom/news/ceramic-matrix-composite-cmc-material-professional-manufacturer-in-chinain general, it is carried out in conjunction with other methodsunder the condition of no cooling structure, it can be used for a long time at 1200°coverview of ceramic matrix composites——advantages

lightweight

high stability

continuous fiber-reinforced ceramic matrix composites are the most outstanding type of materials in ceramic matrix

carbon ceramic composite c/sic

carbon ceramic composite c/sic

composites

excellent mechanical propertiesthe ceramic matrix composite material has a low density (only 1/3~1/4 of the superalloy), and can be used in components such as combustion chambers, regulating plates/sealing plates, and can directly reduce the mass by about 50%continuous fiber reinforced ceramic matrix composites have been widely used in aerospace, national defense and other fields

ceramic matrix composites refer to the introduction of reinforcing materials into the ceramic matrix to form a composite

carbon ceramic composite

carbon ceramic composite

material with the introduced reinforcing material as the dispersed phase and the ceramic matrix as the continuous phasewith the advancement of fiber preparation technology and other related technologies, people have gradually developed effective methods for preparing such materials, making the preparation technology of fiber-reinforced ceramic matrix composites increasingly matureceramic matrix composites can greatly improve the reliability and consistency of materials while maintaining the excellent performance of a single ceramic material such as high temperature resistance, high strength, and low density

liquid silicon infiltration (lsi)

first, carbon fiber is woven into a three-dimensional fabric (hereinafter referred to as carbon fiber preform); a layer of simple silicon with a thickness of 01-2 μm is deposited on the carbon fiber preform by vapor deposition technology; phenolic resin, carbon black, ethanol, ultrafine silicon carbide powder, polyvinylpyrrolidone and tetramethylammonium hydroxide are prepared in proportion to make a mixed slurry; the slurry is pressurized and impregnated into the above-mentioned carbon fiber prefabricated body in a vacuum environment to obtain a composite material green body; the above-mentioned green body is heated and solidified; the cured green body is placed in a vacuum furnace for high-temperature siliconization reaction to obtain a high-density, high-performance carbon-silicon carbide ceramic composite materialit has high strength and high toughnessthe working temperature of ceramic matrix composites is as high as 1650°c, which can simplify or even eliminate the cooling structure, optimize the engine structure, and increase the working temperature of the engine

the manufacturing cycle is long, the cost is high, and the prepared composite material has high porositytubes, missile radomes, space shuttle nose cones, aircraft brake discs, and high-end automobile brake discs have become an important branch of the field of composite materialsit has the characteristics of high temperature resistance, wear resistance, high temperature creep resistance, low thermal conductivity, low thermal expansion coefficient, chemical corrosion resistance, high strength, high hardness and wave penetration, and is widely used in many fields such as aerospacein particular, it has a non-catastrophic fracture mode different from that of a single ceramic, which has attracted great attention from researchers all over the worldceramic matrix composites can maintain high stability in high temperature environments, even in aerobic environments, which reduces the development and application costs of thermal protective coatingsIndia

₹ 11

-

Mdf, or medium density fiberboard, is made by breaking down hardwood or softwood residuals into fine fibers and combining them with resinfurthermore, mdf laminated boards are an eco-friendly choice, as they utilize recycled wood fibers and offer a durable alternative to solid woodcall us now!

greenpanel industries limited

3rd floor, plot no 68, sector 44, gurgaon 122003, haryana

t: 01244784600

toll free number 1800-102-2999 (monday to friday except holidays 10 am to 5 pm)

e: info@greenpanelgreen panel mdf laminated boards are a versatile and cost-effective solution for interior design and furniture applicationslaminated mdf boards are enhanced by adding a decorative laminate layer, which not only improves aesthetics but also increases durability and resistance to moisture, heat, and wearthe laminated finish offers a variety of designs, from wood grains to modern textures, making it easy to match different interior stylesthese boards are widely used in the construction of cabinets, shelves, and wall panels due to their smooth surface and uniform strengthideal for both residential and commercial projects, these boards provide a high-quality finish at a more affordable price pointGurgaon (Haryana)

-

Loreal sculpte fiber paste (holding power 3) amazing product, amazing n silky smooth finish, the fibers give a textured and flexible holdused just twice(google it if you don't believe it) for both men and women

₹ 490

-

Innovative use of the fibers is used to add the comfort and lavish appearance to the beddingthe fiber contains disinfection features which ensure hygienefor comforting living in the chilly weather, homescapes has come with microfiber duvet

₹ 3022

-

Brand new available material: 80% polyster - 20% polyamide, thickness: 300 gsm best for detailing, cleaning and polishing has affinity to oil that allows oil to cling directly to the fibers absorbs 3-4 times its weight of water, being hydrophilic & dries 3x faster than cotton uses only water to clean, needs no cleaning agentslasts as much as 500 washes much more than cotton reliable performance

₹ 250