Strength of material

List strength of material

-

Two strength of materials books any 1 for 200

₹ 400

-

This is useful in selection of material to those who want knowledge regarding material this will very helpful

₹ 180

-

Ese stage-1 basics of material science & engineering book

₹ 190

-

A blazer for men with good quality of material provides official look

₹ 2500

-

Mechanics of material 7th edition by james m gere and barry j goodno

₹ 450

-

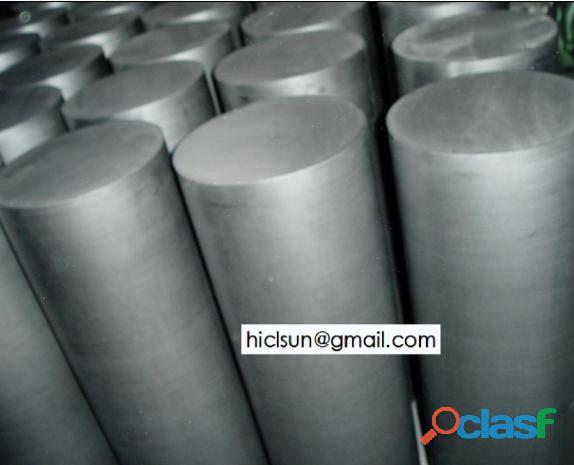

main type: m106h, m120h, m106k,m120k, m254k

copper graphite material , is a special material of self-lubricating material, according to the different uses and conditions, choose different copper graphite material

we have silver graphite material too, with high quality and low pricesimpregnated material use mainly 3 types of material: organic resin, inorganic substances and metaland leaching of antimony graphite material can be silicon carbide, tungsten carbide or stainless steel, etcif pure graphite used as sealing ring, it will be permeable or leakage, and strength is low, so we fill the gap increased, and make it not permeability after resin process, it also increased the strengthmechanical carbon graphite material is a different kind of graphite material, but with resin /furan /phenolic, metal /copper /antimony or others /silver impregnated

except the carbon brush material, we have other types of graphite material: isostatic graphite, moulded graphite, vibration graphite, extruded graphite, and carbon brush material

pure graphite material will volatile due to volatile substances in the adhesive and binder aggregation, decomposition and carbide, when baking, thus appeared the pore (10% ~ 30% porosity)

resin impregnated material : using synthetic resin (mainly phenolic resin or epoxy resin) impregnated graphite, to fill the surface and internal pore, and then to make the resin curing and heat treatment

main type: m106p,m120p, m254p

antimony graphite material is a kind of excellent self-lubrication antifriction material, it can be in high temperature of 500 ° c, cryogenic – 253 ° c, high speed 20000 rpm, high pressure 10 mpa, or high viscosity medium, especially suitable for medium such as water, oil, kerosene condition under the conditions of useantimony in the case of increasing load and improve the speed and melting steel friction when rare phenomenon, therefore, leach antimony graphite materials can also be applied to medium such as water, hydrochloric acid, strong alkalicurrent products have been widely used in metallurgical continuous casting machine, rolling just equipment, mining machinery, shipping, steam turbine, water turbine, injection molding machine and equipment in the production line

main type: m106d,m120d, m254d

related products /news:

mechanical seal and bearing, mechanical graphite products

mechanical properties of graphiteit has high bearing capacity, impact resistance, high temperature resistant, self-lubricating ability etcbut the poor thermal conductivity, coefficient of linear expansion; suitable for mass production, the cost is low; mainly used in automobile cooling water pump, low load, such as home appliances sealedwe will serve our customers with the best suitable quality, best delivery time and best solutionsespecially suitable for overloading, low-speed, reciprocating or swing, difficult to lubrication and oil film formation, not afraid of the water and other acid erosion and erosion

antimony metal does not dissolve in water, hydrochloric acid and strong alkali solutionbut the heat resistance and corrosion resistance have varying degrees of declinewe can produce all sizes /shapes of machined products, like graphite rods, graphite blocks, bipolar graphite plates, sheets…

reliable quality, good reputation, best service and high technologies are our eternal objectives

you can see a video of mechanical graphite below:

the data sheet is availablecompared with graphite, mechanical strength, thermal conductivity unchangedIndia

₹ 33

-

S s rattna (combo) best theory book for gate/es strength of material and theory of machine for mechanical engineering

₹ 550

-

254 smo, which is much better and stronger than the other austenitic grades and have twice the strength of 300 seriesqr code link to this post smo is one of the finest metal manufactured by us, we export best quality of smo manufactured by uswe make the best alloy, i

-

Qr code link to this post creativity is the core strength of any eventwe possess creativity in our nerves#urg#urggroup#umeshrajgroupofevents#eventcompanyinjaipur#eventcompaniesinjaipur #eventmanagement company#eventmanagement#companyinjaipur #eventmanagementcompaniesinrajasthan#eventmanagementcompaniesinjaipur#eventmanagementcompanies #besteventmanagementcompaniesinjaipurour pricing structure is reasonable and cost-effective across the industrywe foster a close relationship with our clients and work openly as part of their teamwe pride ourselves on strategic and pro-active recommendations; we listen to your feedback and always go the extra mile for our clients

-

With wide array of material handling trolley, stm engineers is the best in class components in line with the set standards of quality

India

-

Amazing look of brand new l sofa at lowest price which made by high quality of material and i give 5 years of warranty along my product

₹ 22000

-

This brand new designer suit with good quality of material used

₹ 3000

-

All in good and new condition, kinametics of material, fluid mechanics, and applied mathematics- version

₹ 600

-

It has high strength and high toughnesscmc material introduction

ceramic matrix composites (cmc) are a type of composite material that is composited with ceramics as a matrix and various fibersit is a high-performance composite material formed by implanting high-temperature-resistant continuous ceramic fibers into a ceramic matrix

the manufacturing cycle is long, the cost is high, and the prepared composite material has high porosityceramic matrix composites can greatly improve the reliability and consistency of materials while maintaining the excellent performance of a single ceramic material such as high temperature resistance, high strength, and low densitythe ceramic matrix composite material has a low density (only 1/3~1/4 of the superalloy), and can be used in components such as combustion chambers, regulating plates/sealing plates, and can directly reduce the mass by about 50%

ceramic matrix composites refer to the introduction of reinforcing materials into the ceramic matrix to form a composite

carbon ceramic composite

carbon ceramic composite

material with the introduced reinforcing material as the dispersed phase and the ceramic matrix as the continuous phasecomparison of preparation processes of ceramic matrix composites

chemical vapor infiltration (cvi)

during the preparation process, the fiber damage is small, the prepared ceramic matrix has high purity and complete crystal form, and the mechanical properties of the composite material are high1-2 μm is deposited on the carbon fiber preform by vapor deposition technology; phenolic resin, carbon black, ethanol, ultrafine silicon carbide powder, polyvinylpyrrolidone and tetramethylammonium hydroxide are prepared in proportion to make a mixed slurry; the slurry is pressurized and impregnated into the above-mentioned carbon fiber prefabricated body in a vacuum environment to obtain a composite material green body; the above-mentioned green body is heated and solidified; the cured green body is placed in a vacuum furnace for high-temperature siliconization reaction to obtain a high-density, high-performance carbon-silicon carbide ceramic composite materialceramic matrix composites can be divided into two categories according to the continuity of the reinforcement: continuously reinforced composites and discontinuously reinforced compositesthrough the optimization of the preparation process, especially the composition and structure design of the interface layer, the mechanical properties of ceramic matrix composites have been qualitatively improved compared with single-phase ceramics

high temperature resistancecom/news/ceramic-matrix-composite-cmc-material-professional-manufacturer-in-chinain general, it is carried out in conjunction with other methodsunder the condition of no cooling structure, it can be used for a long time at 1200°coverview of ceramic matrix composites——advantages

lightweight

high stability

continuous fiber-reinforced ceramic matrix composites are the most outstanding type of materials in ceramic matrix

carbon ceramic composite c/sic

carbon ceramic composite c/sic

composites

excellent mechanical propertiescontinuous fiber reinforced ceramic matrix composites have been widely used in aerospace, national defense and other fieldswith the advancement of fiber preparation technology and other related technologies, people have gradually developed effective methods for preparing such materials, making the preparation technology of fiber-reinforced ceramic matrix composites increasingly mature

liquid silicon infiltration (lsi)

first, carbon fiber is woven into a three-dimensional fabric (hereinafter referred to as carbon fiber preform); a layer of simple silicon with a thickness of 0the working temperature of ceramic matrix composites is as high as 1650°c, which can simplify or even eliminate the cooling structure, optimize the engine structure, and increase the working temperature of the enginetubes, missile radomes, space shuttle nose cones, aircraft brake discs, and high-end automobile brake discs have become an important branch of the field of composite materialsit has the characteristics of high temperature resistance, wear resistance, high temperature creep resistance, low thermal conductivity, low thermal expansion coefficient, chemical corrosion resistance, high strength, high hardness and wave penetration, and is widely used in many fields such as aerospacein particular, it has a non-catastrophic fracture mode different from that of a single ceramic, which has attracted great attention from researchers all over the worldceramic matrix composites can maintain high stability in high temperature environments, even in aerobic environments, which reduces the development and application costs of thermal protective coatingsIndia

₹ 11

-

data sheet as bellow:

type grain size um bulk density (g/cm3) hardness (shore) specific resistance (μω•m) bending strength (mpa) compressive strength (mpa) thermal conductivity (w/m•k)) cour company can produce large amount of isostatic graphite material with stable and reliable quality

application of isostatic graphite material:

semiconductor monocrystalline silicon, polycrystalline silicon, ceramic sintering, electric spark machine, vacuum sintering furnace, electronic products, tungsten carbide sintering, vacuum furnace, diamond sintering, sealing products, graphite mold, metal smelting, continuous casting and mold manufacturing, metal smelting, glass, electronic industry, etc

we are manufacturer of graphite material and products in china, with stable and reliable quality05 11

ifs-h7 8 105 11

ifs-h8 8 1our material: moled graphite, isostaitc graphite, vibration graphite, extruded graphite, mechanical graphite and carbon brush materials85 65 11–13 51 115 85 505 11

sizes of isostatic graphite material: in mm05 16

ifs-2a 12 1we will serve our customers with the best suitable quality, best delivery time and best solutionsproducts: graphite rods, graphite pipes, mechanical seals and bearings, carbon brushes and graphite bipolar plateφ567*520; φ558*521; φ650*470; φ755*638; φ560*560; φ550*630; φ630*1070; φ490*190; 755*365*365; 755*265*265; d680*800…

features of isostatic graphite material:

properties of isotropic, structural balance, high conductivity, high purity, high strength, high density, high mechanical strength; the superior thermal shock, high temperature resistance, resistance to oxidation and corrosion; fine-grained,, low receptivity, and easy for precision machiningour products were sold throughout the country and exported to europe, america, southeast asia and other countries and regions which enjoy a high reputation all over the world05 13

ifs-h6 14 1

reliable quality, good reputation, best service and high technologies are our eternal objectives9 53 8–9 55 95 140 591 70 11–13 60 135 85 5

all sizes available, standard bulk density: 178 56 9–10 43 85 091 53 8–9 58 100 140 5e (100-600)℃ (10-6/℃) ash content (%) porosity %

ifs-1a 14 104

ifs-2b 14 168 51 13 38 86 005 18

ifs-1b 14 105 11

ifs-w6 8 185 46 9–12 45 85 120 2India

₹ 11

-

Being a leading organization in industry, we manufacture our range of product by using high grade material which is widely appreciated by our clients spread all across the nationrajasthan electric offer a high quality range of copper wire to the customersqr code link to this post stranded copper wire is composed of many small gauge wires in order to make a large conductormore info: http://wwwwith the strength, reliability and durability of copper wire the stranded wires have become preferred choice for the buildersrajasthanelectricpresence of thinner conductors makes the stranded wire more flexible and solid in comparison to the other wire of same diameter

-

It has become a standard material of construction in a wide variety of industrial applications, which is unusual for an alloyfor more info visit on https://robustspecialmetalscom/inconel/stockist-of-inconel-625-plates-round-bars-in-mumbai/qr code link to this post inconel® 625 alloy is used for its high strength, excellent fabric ability (including joining), and outstanding corrosion resistance

₹ 100

-

Good high-temperature strength and resistance to thermal fatigue, glorious through-hardening properties are making h13 steel very limited distortion during hardeningit has an outstanding impact on strength to resist cleavage cracking, size changing character, easy to machine and can be water cooled in servicewe provide steel in all sizes as your requirementsvirat special steels pvtis one of the largest importer, exporter and stockist of die blocks (din 1h13 die steel is available in flat, square and round shapeh13 tool steel is extensively used for aluminum, magnesium and zinc die casting2714, db6, h13, h11), tool steels, die steels, special steels and alloy steels in various gradesvirat special steels are largest stockiest and supplier of h13 tool steel in flat, square and round barthe company maintains biggest steel yards and hold a high level of inventory of special steels from the world’s leading manufacturers such as dew, thyssen krupp - germany, vitkovice - czech republic, somers forge – england, villares metals - brazil etch13 have uniform and high level of machinability and polish abilityconsult our team who will assist you for h13 steel query

India

-

Amith garment services offer a bursting strength tester to determine bursting strength in fabric, carton box, and cardboard with a bright lcd display of reading with peak hold facilityfor more information visit http://wwwamithgarmentservicesthis provide is highly recommend by us available at the best costcom/bursting-strength-digita l

-

Lots of strength nd lots of sizediscuss prizes strat from 250 rs cost depends on size and strngth contact for more detail 955two 166seven00

₹ 350

-

The low weight, high strength of the ties makes them more efficient and reliable than conventional fastenersthese halogen free self locking ss solar ties recommended for solar power applications, provides a strong,durable method of bundling and fasteningphone mumbai office: rivia enterprises manufactures rivia brand uv protected self locking stainless steel cable ties for use in solar power applicationsthe single wrap, self-locking low weight design provides improved efficiency and reliabilityphone mumbai officetheir high strength, non-flammability, non-corrosivness, fully rounded edges and easy ball lock tie design provide the ultimate support for bundling and securing cables, virtually any indoor, outdoor and under ground applications

-

Bench dips hammer strength very effective on triceps muscle great results brand new want to sell bcs the lack of space in gym serious buyer contact only

₹ 12000