Sealing

List sealing

-

I am sealing my new counter with neat conditions instead person call me

₹ 2500

-

sealing machine for more details plz contact prasana devi lodge

₹ 30000

-

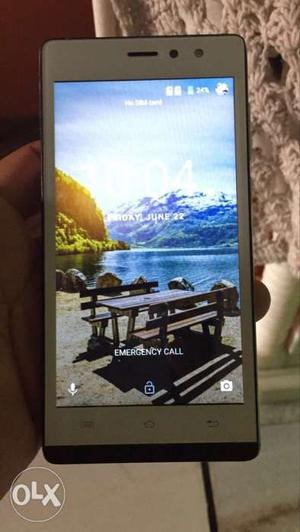

Hlo guys i m sealing my lava phone a97 gold colour fine working everything is working i have bill charger handfree 4g phone jio sim is properly working

₹ 3100

-

Just few months old, in used sealing machine(12 inches) for sale

₹ 2500

-

Qr code link to this post available sealing wax in red colour 20 sticks 375 grams pkt 8 sticks,375 grams pkt 3 kgs pkt contact indian wax industries bhandari street 3 mahavir darshan near axis bank & masjid bunder west mumbai- p 91- show contact info - m = show contact info web http://wwwcom show contact info

-

Qr code link to this post preformed pouch sealing machine is a semi automatic machineinnovative pack tech manufacture this machine o make your work easy in every industryfor more details visit - http://innovativepacktechcom/preformed-pouch-sealing-machine-band-sealer-manufacturer-noida contact - address- plot no 120, udyog kendra ext–ii, sector–ecotech-iii, greater noida, uthis machine ihas an inbuilt cooling system which increase its lifetime

-

Innovativepacktech that is the semi-automatic sealing machinethe machine adopts electronic constant temperature mechanism and steeples speed adopts electronic constant temperature mechanism and steeples speed adjusts transmission mechanism, it can seal plastic film in various kinds of materials

Noida (Uttar Pradesh)

-

Qr code link to this post liquid sealing machine to seal milk packets, oil packets, etcexcellent for small scale production units

₹ 9999

-

These tin cap sealing machine are resistant to rust and require minimal adjustmentused to fill the uniform, the filling method of these machines is easily adjusted to different volumeswe have an outsized sort of highly efficient and sturdy range of dual nozzle rotary nozzle filling machines manufactured with high-quality materials

India

₹ 1

-

These plastic bottle sealing machine and equipment ensure hygienic workspaces, high production output, high speeds, and in-budget manufacturing costsa capping machine’s main function is to employ a plastic or metal lid, snap, or caps accurately and securely to a jar, container, or bottlecap closing machines are essential equipment used in bottling automation industries

India

₹ 1

-

We are a leading manufacturer and supplier of bread sealing machinethe operating procedure of these machines is that after putting the baked goods in a plastic bag, you simply run the whole bag into the machine to get a clear closure, thus keeping the baked goods fresh and safethese are ready to cover baking supplies

India

₹ 1

-

usage:

installation: install the marine butterfly valve correctly according to manufacturer specifications, ensuring proper alignment, bolt torquing, and gasket sealing between flanges

sealing material: consider the type of sealing material based on temperature, pressure, and fluid properties to ensure reliable performance and longevity

resilient seating: many marine butterfly valves feature resilient seating made of materials like epdm or nbr, which offer excellent sealing properties and resistance to wear, corrosion, and chemicals

bidirectional sealing: butterfly valves are inherently bidirectional, meaning they can effectively seal flow in both directions, allowing flexibility in installation and operation

material compatibility: select materials compatible with the fluids being handled and resistant to corrosion in the marine environmentby considering these factors and adhering to best practices for selection, installation, operation, and maintenance, marine butterfly valves can effectively control flow and contribute to the safe and efficient operation of ship systemsa butterfly valve used in marine applications, often referred to simply as a marine butterfly valve, is a critical component in ship systems for controlling the flow of fluids such as water, fuel, and various other liquids

manual or actuated operation: marine butterfly valves can be operated manually using a hand lever or wheel, or they can be equipped with pneumatic, electric, or hydraulic actuators for remote operation and automation

emergency response: establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions

selection considerations:

size and pressure rating: choose a valve size and pressure rating suitable for the intended application and system requirements aboard the ship

here’s an overview features:

corrosion resistance: marine environments expose valves to corrosive elements like saltwater

operation type: determine whether manual or actuated operation is preferable based on accessibility, control requirements, and automation needs

compact design: space is often limited aboard ships, so marine butterfly valves are designed to be compact and lightweight while still providing efficient flow controlhence, marine butterfly valves are typically made from materials such as bronze, stainless steel, or other corrosion-resistant alloys

compliance and certification**: ensure the selected valve meets relevant industry standards and certifications for marine applications, such as those from classification societies like dnv, abs, or lloyd’s register

maintenance: implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and reliability

monitoring: periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazards

operation: operate the valve using the designated controls, whether manual or actuated, following established procedures for opening, closing, and adjusting flow rates as neededIndia

₹ 13827

-

gate valves generally have two sealing surfaces, adding some difficulties to processing, grinding and maintenance

during the opening and closing process, there is relative friction between the sealing surfaces, which can easily cause scratchesusually, the sealing surface will be welded with metal materials to increase wear resistance, such as 1cr13, stl6, stainless steel, etc

the structure is compact, the valve has good rigidity, the channel is smooth, the flow resistance is small, the sealing surface is made of stainless steel and hard alloy, and the service life is long

the medium can flow in any direction on both sides, easy to installthe use of ptfe packing is reliable and easy to operatea gate valve is a gate plate of an opening and closing part

related types of valves:

we can also produce check valve, globe valve, knife gate valve and ball valve with api, jis, din standard, used in oil, gas, marine industry, water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with nominal diameter of dn50 to dn1200, nbr/epdm/viton, certificates & approvals: dnv-gl, lloyds, dnv, bv, api, abs, ccs5

face to face dimensions conform to en558-1, api 594, din3202

testing conform to en12266-1, api598

material of gate valve parts

part name material

body cast iron; ductile iron; stainless steel; carbon steel

disc / flap stainless steel; carbon steel; bronze

shaft / stem brass, stainless steel monel; stainless steel inconel

seat / lining nbr/epdm/viton

ss/bronze

bolts carbon steel

nuts stainless steel

gasket/packing graphite

name plate aluminum

washer steel

handwheel cast iron

bushing/ring cast brass

actuation

worm-gear/hand-wheel

electric-actuator

pneumatic-actuator

hydraulic-actuator

gate valve features

advantages:

low flow resistancestandards: en 593, api609, api6d,

more video of gate valve, please see: https://wwwcom/watch?v=ai-lt1dy2su

materials: cast iron / ductile iron/ carbon steel / stainless

steel / alu bronze

pressure rating: pn10, pn16, pn25

temperature: -30°c to 200°c

seat/lining: replaceable liner / bonded liner

nbr/epdm/viton; ss/bronze

certificates & approvals: dnv-gl, lloyds, dnv, abs, bv type approval

3

large height and long opening and closing time

the structure length is small

area of application

marine industry, water supply & drainage, fire fighting, shipbuilding, water treatment, power stations, energy, food, chemical, and other systems

data sheet of gate valve:

type: wafer, double flange

size & connections: resilient seated: dn50 to d600

metal seated: dn50 to dn1200

medium: waste water, water, seawater, air, inert gas, oil

disadvantages

the overall dimensions and opening height are largethe movement direction of the gate plate is perpendicular to the direction of the fluidthe reason is the long shutdown timethe gate valve is sealed by the contact of the valve seat and the gate plate

less effort when opening and closingthe gate valve can only be fully opened and fully closed, and cannot be adjusted or throttledthe gate has a rigid gate and an elastic gatethe space required for installation is largeaccording to the different gate plates, the gate valve is divided into a rigid gate valve and an elastic gate valve2 cert (on request)

standards

design and manufacture conform to awwa, bs5163, din-f4,f5

dimensions conform to en1092-2,ansi b16

the shape is simple, the structure length is short, the manufacturing process is good, and the application range is wide

water hammer phenomenon is not easy to produceIndia

₹ 1

-

Temperature, viscosity, chemical compatibility) and sealing requirements

resilient seating: most wafer concentric butterfly valves come with resilient seat materials such as epdm or nbr, which provide excellent sealing properties and resistance to wear, corrosion, and chemicalsthis compact design saves space and facilitates easy installation and removalhere’s a brief overview of its features, selection considerations, and usage:

features:

concentric design: the wafer concentric butterfly valve features a concentric design where the stem passes through the center of the disc, ensuring a uniform seal around the circumferenceconsider factors such as flow rate, system pressure, and compatibility with existing piping

material construction: select valve materials compatible with the fluid being handled and the environmental conditionsmanual valves are operated by hand, while actuated valves can be controlled remotely using pneumatic, electric, or hydraulic actuators for automated flow controlcommon materials include stainless steel, carbon steel, ductile iron, and various alloys

bidirectional sealing: the concentric design allows for bidirectional sealing, meaning the valve can be installed in either direction without affecting its performance

emergency response: establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions

operation: operate the valve manually or remotely using the designated controls, following established procedures for opening, closing, and adjusting the flow as needed

selection considerations:

size and pressure rating: choose a valve size and pressure rating suitable for the intended application and operating conditionsthis design minimizes turbulence and pressure drop while providing efficient flow control

seat material: consider the type of seat material (e

usage:

installation: properly install the wafer concentric butterfly valve between flanges using appropriate gaskets and fasteners according to manufacturer specifications and industry standards

by considering these factors and following best practices for selection, installation, and maintenance, wafer concentric butterfly valves can effectively control flow and provide reliable performance in marine applications and other industrial settings

wafer style: these valves have a wafer-style body, which means they fit between two flanges without the need for additional bolts or nuts

monitoring: periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazardsepdm, nbr, ptfe) based on the fluid properties (e

manual or actuated operation: wafer concentric butterfly valves are available in manual or actuated configurations

standards compliance: ensure the selected valve complies with relevant industry standards and certifications for quality, performance, and safety, such as ansi, api, iso, and marine classification societies’ requirementsa wafer concentric type butterfly valve is a type of butterfly valve commonly used in various industries, including marine applications

operation type: decide whether manual or actuated operation is preferred based on the level of automation required, accessibility, and control system integration

maintenance: implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and longevityIndia

₹ 13827

-

Temperature, viscosity, chemical compatibility) and sealing requirements

rubber seating: the valve has rubber or elastomeric seating, typically made from materials like epdm or nbr, which provide excellent sealing properties

selection considerations:

size and pressure rating: choose a valve size and pressure rating suitable for the intended application and operating conditionsrubber seats offer resilience, chemical resistance, and longevity, making them suitable for various fluids and operating conditionsconsider factors such as flow rate, system pressure, and compatibility with existing piping

material construction: select valve materials compatible with the fluid being handled and the environmental conditionsmanual valves are operated by hand, while actuated valves can be controlled remotely using pneumatic, electric, or hydraulic actuators for automated flow controlcommon materials include stainless steel, carbon steel, ductile iron, and various alloys

emergency response: establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions

operation: operate the valve manually or remotely using the designated controls, following established procedures for opening, closing, and adjusting the flow as needed

by considering these factors and following best practices for selection, installation, and maintenance, lug concentric butterfly valves with rubber seating can effectively control flow and provide reliable performance in marine applications and other industrial settings

bidirectional sealing: similar to other concentric butterfly valves, this type can seal bidirectionally, allowing it to be installed in either direction without affecting its performancethis design minimizes turbulence and pressure drop while providing efficient flow control

lug style: the valve body has lugs (also known as ears or tabs) on the valve’s periphery, allowing it to be bolted directly between flanges in the pipeline

seat material: consider the type of seat material (ethis design provides easy installation and removal without needing to disconnect the entire pipelinea lug concentric type butterfly valve with rubber seated refers to a specific configuration of a butterfly valve commonly used in various industries, including marine applications

monitoring: periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazards

manual or actuated operation: lug concentric butterfly valves are available in both manual and actuated configurationsepdm, nbr, ptfe) based on the fluid properties (elet’s break down its features, considerations for selection, and how it’s typically used:

features:

concentric design: like other concentric butterfly valves, this type features a design where the stem passes through the center of the disc, ensuring a uniform seal around the circumference

standards compliance: ensure the selected valve complies with relevant industry standards and certifications for quality, performance, and safety, such as ansi, api, iso, and marine classification societies’ requirements

operation type: decide whether manual or actuated operation is preferred based on the level of automation required, accessibility, and control system integration

maintenance: implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and longevity

usage:

installation: properly install the lug concentric butterfly valve between flanges using appropriate gaskets and fasteners according to manufacturer specifications and industry standardsIndia

₹ 13827

-

paper carry bag manufacturer, non woven carry bags suppliers,custom paper carry bag, plastic carry bag suppliers from chinaexquisite edge sealing, even force to prevent damage, strong sealing, not easy to leakthe surface embossing is clearly visible, the texture is delicate and the hand feels comfortableselected high-quality pe materials, non-toxic and tasteless, safe and securethe shackle design is more convenient to use and takeKavaratti (Lakshadweep)

₹ 6

-

In the known butterfly valve technology, its sealing form is mostly sealed structure, sealing materials for rubber, ptfe, etc

below photos are ptfe lined butterfly valve of tianjin tanghai valve, more information please click here: ptfe butterfly valveit can replace the stainless steel body under conventional conditions, with higher cost performancedue to the limitation of structural characteristics, it is not suitable for high temperature resistance, high pressure resistance, corrosion resistance, wear resistance and other industriesthe butterfly plate of the butterfly valve is installed in the diameter direction of the pipe

ptfe (teflon) butterfly valve can be equipped with akr electric, by pneumatic actuator, input control signal (4~20madc or 1~5vdc) and single-phase power supply can control the operation, can realize intelligent type (regulating type) and switching type

th valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with api, jis, din standard, used in oil, gas, marine industry, water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with nominal diameter of dn50 to dn1200, nbr/epdm/viton, certificates & approvals: dnv-gl, lloyds, dnv, bv, api, abs, ccsstandards: en 593, api609, api6dwith strong function, small size, light and pleasant, reliable performance, simple supporting, large circulation capacity, especially suitable for the medium is sticky, containing particles, fiber properties of the occasionin the cylindrical channel of the butterfly valve body, the disc shaped butterfly plate rotates around the axis, the rotation angle is 0°~90°, rotate to 90°, the valve brand is fully open

at present, the ptfe butterfly valve, as a component used to realize the on-off and flow control of the pipeline system, has been widely used in petroleum, chemical industry, metallurgy, hydropower and many other fieldsptfe butterfly valve is to adapt to some corrosive environment with strong acid, strong alkali, petroleum, chemical, food and other special areas of need, the use of ptfe made of the valve body, has a strong anti-corrosion effectIndia

₹ 1

-

The double-door check valve adopts clamping type, the butterfly plate is two semicircle, and the sealing surface can be body surfacing wear-resistant material or rubber lining, wide range of use, reliable sealing

check valve opening and closing parts by the medium flow and force to open or close, to prevent the medium backflow of the valve called check valve

if you need more information, please click here: dual plate swing check valve, you can get more information here

th valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with api, jis, din standard, used in oil, gas, marine industry, water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with nominal diameter of dn50 to dn1200, nbr/epdm/viton, certificates & approvals: dnv-gl, lloyds, dnv, bv, api, abs, ccsstandards: en 593, api609, api6dthe dual plate check valve is used for pure pipeline and industrial, environmental protection, water treatment, high-rise building water supply and drainage pipeline, to prevent the reverse flow of the mediumcheck valves belong to automatic valves, mainly used for medium one-way flow on the pipeline, only allow the medium to flow in one direction, in order to prevent accidentsIndia

₹ 1

-

Com

for more info : hand sealer machine | pepsi pouch sealing machine

https://wwwa bag-closing machine is a type of industrial equipment used for closing or sealing bags, typically in manufacturing or packaging processesbiz/items/bag-closing-machine?utm_source=seo&utm_medium=classified&utm_campaign=bagcloser

visit for more details:

https://smartpackindia9713032266

whatsapp : 9827035264

email : sales@smartpackindiathese machines are designed to efficiently and securely close bags, ensuring that the contents are protected and containedcom/smartpackindia

https://smartpackindiabag-closing machines are widely used in various industries, including agriculture, food processing, chemical, pharmaceuticals, and morebiz/

contact nocom/smartpackindia/

https://twitterIndore (Madhya Pradesh)

₹ 452001