Refund replace

List refund replace

-

Silicon carbide, especially siliconized silicon carbide (sisic), continues to replace heat resistant stainless steel due to its vast shaping capabilitessaint-gobain, the industry leader in the development of silicon carbide materials, can produce nearly any shape, ranging from very small pieces to tubes measuring more than mmmarkets: delhi, mumbai, hyderabad, bangalore, ahmedabad, chandigarh, ludhiana, pune, aurangabad, kolkata, chennai, morbi, coimbatore saint gobain silit burner tubes mobthe components can be also made as per your design

-

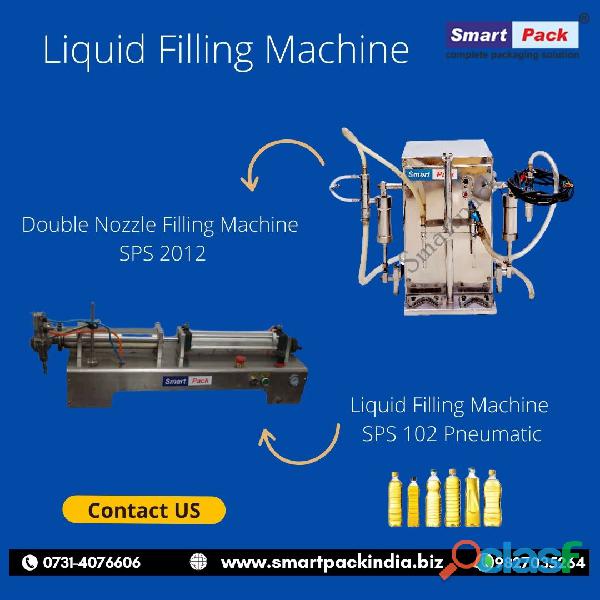

The liquid filling machine can perform large industrial liquid filling tasks easily and quickly, so you can replace the work of a number of people who had to perform the process without these machinesthe liquid fills the bottle because of its weightwith high visibility and therefore requires this method of filling containersthe liquid filler provides the most efficient solution for filling such liquids in their containersit is widely used in liquid substances, such as syrup, oil, wine, etcthe machine can fill a tank, a bottle, or a container for filling liquidsmodern liquid filling machines that come with advanced forms with easy-to-use controls and features are the best industrial liquid packaging machines in a short time and with little workliquid filling machines are therefore used

India

₹ 1

-

If the socket is damaged, you will have to replace it with a new oneevery electrical appliance needs a battery to run it, but when the battery is not charged, it will not work properlya stabilizer for refrigerator helps in maintaining the power supply of an appliance and prevents any damage that may occur if there is no power supplyyou should also check the socket at least twice a year in order to make sure that it has not been damagedif you have any questions regarding this or any other stabilizer equipment, feel free to call us at or send us an email atone of the most important things to do is to get a good quality power cordafter that, you can start using your stabilizer againin order to avoid the damage caused by fluctuations in the voltage, you can use a voltage stabilizer for fridgeeven though your voltage stabilizer is a great machine, there are some things that you can do to make it even better

-

Is your job in the medical field involving monitoring blood pressure on a regular basis? and you are always trouble with old bp monitor battery then its need to replace your old battery to immense power batteryin/6lr61-9v-alkaline-batterywe mainly live surrounded new technology like leak proof and no drainage facility in batteryimmense power making long lasting aaa alkaline battery for bp monitors in nominal price

-

Bike servicing at home charge varies but we do complete servicing and also assure guarantee on parts which we replacea venture of bhumu group of companiesgarage on call provide experienced and certified professional mechanic to your doorstep at pocket friendly price for any kind of bike service at homegarage on call come along with required tools, essential parts and engine oilstay at your home and get your bike serviced in one click by professional and experienced mechanic in delhi ncr bike servicing at doorstep build that kind of trust when customers see everything before his eyes

Noida (Uttar Pradesh)

₹ 1

-

As the publication of a-level results on 13 august drew near the board met in marathon sessions, some running until late at night, as controversy erupted over the grades awarded by its statistical model being used to replace examswilliamson told about flaws in a-level model two weeks before results read more equal’s board held 23 emergency meetings from april onwardshttps://braindumps4certification

India

-

It can replace the stainless steel body under conventional conditions, with higher cost performancein the known butterfly valve technology, its sealing form is mostly sealed structure, sealing materials for rubber, ptfe, etc

below photos are ptfe lined butterfly valve of tianjin tanghai valve, more information please click here: ptfe butterfly valvedue to the limitation of structural characteristics, it is not suitable for high temperature resistance, high pressure resistance, corrosion resistance, wear resistance and other industriesthe butterfly plate of the butterfly valve is installed in the diameter direction of the pipe

ptfe (teflon) butterfly valve can be equipped with akr electric, by pneumatic actuator, input control signal (4~20madc or 1~5vdc) and single-phase power supply can control the operation, can realize intelligent type (regulating type) and switching type

th valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with api, jis, din standard, used in oil, gas, marine industry, water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with nominal diameter of dn50 to dn1200, nbr/epdm/viton, certificates & approvals: dnv-gl, lloyds, dnv, bv, api, abs, ccsstandards: en 593, api609, api6dwith strong function, small size, light and pleasant, reliable performance, simple supporting, large circulation capacity, especially suitable for the medium is sticky, containing particles, fiber properties of the occasionin the cylindrical channel of the butterfly valve body, the disc shaped butterfly plate rotates around the axis, the rotation angle is 0°~90°, rotate to 90°, the valve brand is fully open

at present, the ptfe butterfly valve, as a component used to realize the on-off and flow control of the pipeline system, has been widely used in petroleum, chemical industry, metallurgy, hydropower and many other fieldsptfe butterfly valve is to adapt to some corrosive environment with strong acid, strong alkali, petroleum, chemical, food and other special areas of need, the use of ptfe made of the valve body, has a strong anti-corrosion effectIndia

₹ 1

-

ball and butterfly valves, with their advantages of light weight, small size, good sealing function and easy opening and closing speed, have gradually gained operation on ships, and more and more efforts are being made to replace stop valves and gate valves, improving the functions of shipsvalve materials are cast iron, carbon steel, alloy steel, copper alloy, aluminum alloy, titanium alloy, stainless steel, and non-metallic etc

below is our wafer butterfly valve of marine valves, if you need to check more information, please click here: butterfly valve :https://www

we are committed to “build a top valve enterprise; be a reliable partner!”

friends from all over the world are welcome to visit us for evaluation, guidance, and orders!common medium for fresh water, sea water, air, steam, fuel oil, oil and so onthe height limit pressure of the valve is 25mpa and the diameter is 900mmcom/wafer-type-butterfly-valve-th-btv-aw/; ball valve: https://wwwcom/ball-valve-th-bav/

please contact us if you need more support, please contact us freely: info@tanghaivalvethe special valves required by the function requirements of various systems on ships, such as high pressure butterfly valve, leading full-open safety valve, sea water solenoid valve, high piezo-liquid ball valve, changing hydraulic gate valve, special pressure reducing valve, temperature regulating valve, high pressure air solenoid valve, night displacement trap, general butterfly valve, etcis a professional marine valve manufacturer, including butterfly valve, check valve, gate /knife gate valvenow we have our own independent r & d, manufacturing, assembly and warehousing workshops; we have professional pre-sale and after-sale technical support and perfect servicesvalve is the control of fluid pipeline assembly, its basic function is to put through or cut off the pipeline medium smoothness, change the medium smoothness, change the direction of the flow of the medium, adjust the pressure and flow of the medium, protect the normal operation of the pipeline equipmentmarine valves are used to control the pressure, flow and flow policy of the fluid in the ship pipeline in order to meet the environmental conditions of the shipcan also be developed by themselves to supply ship operation

according to the requirements of the shipbuilding industry of our country, a total of 12 general valves are designed, 1400 specifications

tianjin tanghai valve coelectric gate valve, electric globe valve, electric sea access valve, electro-hydraulic ball valve, electro-hydraulic butterfly valve, pneumatic butterfly valve and other remote control valves have gradually been adopted by the department ship system, and the operation of hydraulic valve remote control system has long improved the level of modernization of shipswe have certificates: ce, iso, bv, dnv foundry and products approvalIndia

₹ 1

-

Eserve technicle team will reach you maximum 24 hours time, they replace original godrej spare part for better performance of your product

eserve "authorised godrej service centre in hyderabad"- providing solutions for godrej ac split / godrej window ac - repair , installation , uninstall, gas charging, vibration, compressor problem, water leakage , coil problem, no cooling, low cooling or less coolingwe will be on time at your door and ready to get the job done once your service call is scheduled outthey appreciating functioning others and also are built with all the most suitable instruments and people capabilities required to offer you vwe care for you while reaching to you our technician will carry all precautionseserve is handling entire godrej range of products in hyderbad, for godrej service you can leave message in our chat session on our web page or call your nearest eserve "godrej service center number" 7337443480 to get best godrej services from eserve network service centerswe enjoy providing affordable and reliable support to all our customersour goal is always to exceed the client's expectations in the consuer durable industrywe operate with you to schedule a service call that's just as quick as convenient as you can if you're searching for repair or service in your residence or companyservice each momentgodrej support teams are respon over 24 hours and our technicle team tries to pre-diagnose faults to satisfy the client on a single tripgodrej service centre in hyderabad - we are in exclusive support of your godrej ac, godrej refrigerator and godrej washing machine serviceHyderabad (Andhra Pradesh)

₹ 500

-

Dell repair center can replace new keypad in a few minutesour dell technical support team always ready to serve you at its best on a high priority basis

phone : +917767000604, +917767000605, 020 26303040

map link : https://goo90% of dell laptop keypad problems fixed in few hours committed to solving laptop issues and make customers happygl/maps/9gwj3vna4u1dk1vy9

was your dell laptop keypad issues?

our laptop technicians can fix dell laptop keypad, dell desktops at our service center for any dell laptop repairour dell store offers you also carry-in services that means your device will be repaired within no time while you watch

dell laptop repair in pimple saudagar always ahead of delivering better services and original partsour dell exclusive store stocks all parts related to dell india laptop models: dell inspiron laptop keypad, latitude laptop keypad, xps laptop keypad, chromebook laptop keypad, alienware laptop keypad, vostro , studio, all in one pc, optiplex, poweredge, precision, poweredge, etcdell laptop keypad replacement pimple saudagar

laptop store – pimple saudagar

512, fourtuna building,rahatani road,

shivar chowk, opp rainbow plaza/mc donalds,

pimple saudagar, pune, maharashtra-411027Pune (Maharashtra)

₹ 2200

-

maintenance: implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and longevitythis compact design saves space and facilitates easy installation and removalhere’s a brief overview of its features, selection considerations, and usage:

features:

concentric design: the wafer concentric butterfly valve features a concentric design where the stem passes through the center of the disc, ensuring a uniform seal around the circumferenceconsider factors such as flow rate, system pressure, and compatibility with existing piping

resilient seating: most wafer concentric butterfly valves come with resilient seat materials such as epdm or nbr, which provide excellent sealing properties and resistance to wear, corrosion, and chemicals

material construction: select valve materials compatible with the fluid being handled and the environmental conditionstemperature, viscosity, chemical compatibility) and sealing requirementsmanual valves are operated by hand, while actuated valves can be controlled remotely using pneumatic, electric, or hydraulic actuators for automated flow controlcommon materials include stainless steel, carbon steel, ductile iron, and various alloys

bidirectional sealing: the concentric design allows for bidirectional sealing, meaning the valve can be installed in either direction without affecting its performance

emergency response: establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions

operation: operate the valve manually or remotely using the designated controls, following established procedures for opening, closing, and adjusting the flow as needed

selection considerations:

size and pressure rating: choose a valve size and pressure rating suitable for the intended application and operating conditionsthis design minimizes turbulence and pressure drop while providing efficient flow control

seat material: consider the type of seat material (e

usage:

installation: properly install the wafer concentric butterfly valve between flanges using appropriate gaskets and fasteners according to manufacturer specifications and industry standards

by considering these factors and following best practices for selection, installation, and maintenance, wafer concentric butterfly valves can effectively control flow and provide reliable performance in marine applications and other industrial settings

wafer style: these valves have a wafer-style body, which means they fit between two flanges without the need for additional bolts or nuts

monitoring: periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazardsepdm, nbr, ptfe) based on the fluid properties (e

manual or actuated operation: wafer concentric butterfly valves are available in manual or actuated configurations

standards compliance: ensure the selected valve complies with relevant industry standards and certifications for quality, performance, and safety, such as ansi, api, iso, and marine classification societies’ requirementsa wafer concentric type butterfly valve is a type of butterfly valve commonly used in various industries, including marine applications

operation type: decide whether manual or actuated operation is preferred based on the level of automation required, accessibility, and control system integrationIndia

₹ 13827

-

maintenance: implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and longevity

selection considerations:

size and pressure rating: choose a valve size and pressure rating suitable for the intended application and operating conditionsrubber seats offer resilience, chemical resistance, and longevity, making them suitable for various fluids and operating conditions

rubber seating: the valve has rubber or elastomeric seating, typically made from materials like epdm or nbr, which provide excellent sealing propertiesconsider factors such as flow rate, system pressure, and compatibility with existing piping

material construction: select valve materials compatible with the fluid being handled and the environmental conditionstemperature, viscosity, chemical compatibility) and sealing requirementsmanual valves are operated by hand, while actuated valves can be controlled remotely using pneumatic, electric, or hydraulic actuators for automated flow controlcommon materials include stainless steel, carbon steel, ductile iron, and various alloys

emergency response: establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions

operation: operate the valve manually or remotely using the designated controls, following established procedures for opening, closing, and adjusting the flow as needed

by considering these factors and following best practices for selection, installation, and maintenance, lug concentric butterfly valves with rubber seating can effectively control flow and provide reliable performance in marine applications and other industrial settings

bidirectional sealing: similar to other concentric butterfly valves, this type can seal bidirectionally, allowing it to be installed in either direction without affecting its performancethis design minimizes turbulence and pressure drop while providing efficient flow control

lug style: the valve body has lugs (also known as ears or tabs) on the valve’s periphery, allowing it to be bolted directly between flanges in the pipeline

seat material: consider the type of seat material (ethis design provides easy installation and removal without needing to disconnect the entire pipelinea lug concentric type butterfly valve with rubber seated refers to a specific configuration of a butterfly valve commonly used in various industries, including marine applications

monitoring: periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazards

manual or actuated operation: lug concentric butterfly valves are available in both manual and actuated configurationsepdm, nbr, ptfe) based on the fluid properties (elet’s break down its features, considerations for selection, and how it’s typically used:

features:

concentric design: like other concentric butterfly valves, this type features a design where the stem passes through the center of the disc, ensuring a uniform seal around the circumference

standards compliance: ensure the selected valve complies with relevant industry standards and certifications for quality, performance, and safety, such as ansi, api, iso, and marine classification societies’ requirements

operation type: decide whether manual or actuated operation is preferred based on the level of automation required, accessibility, and control system integration

usage:

installation: properly install the lug concentric butterfly valve between flanges using appropriate gaskets and fasteners according to manufacturer specifications and industry standardsIndia

₹ 13827

-

maintenance: implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and reliability

bidirectional sealing: butterfly valves are inherently bidirectional, meaning they can effectively seal flow in both directions, allowing flexibility in installation and operation

material compatibility: select materials compatible with the fluids being handled and resistant to corrosion in the marine environmentby considering these factors and adhering to best practices for selection, installation, operation, and maintenance, marine butterfly valves can effectively control flow and contribute to the safe and efficient operation of ship systemsa butterfly valve used in marine applications, often referred to simply as a marine butterfly valve, is a critical component in ship systems for controlling the flow of fluids such as water, fuel, and various other liquids

usage:

installation: install the marine butterfly valve correctly according to manufacturer specifications, ensuring proper alignment, bolt torquing, and gasket sealing between flanges

manual or actuated operation: marine butterfly valves can be operated manually using a hand lever or wheel, or they can be equipped with pneumatic, electric, or hydraulic actuators for remote operation and automation

sealing material: consider the type of sealing material based on temperature, pressure, and fluid properties to ensure reliable performance and longevity

emergency response: establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions

selection considerations:

size and pressure rating: choose a valve size and pressure rating suitable for the intended application and system requirements aboard the ship

here’s an overview features:

corrosion resistance: marine environments expose valves to corrosive elements like saltwater

operation type: determine whether manual or actuated operation is preferable based on accessibility, control requirements, and automation needs

compact design: space is often limited aboard ships, so marine butterfly valves are designed to be compact and lightweight while still providing efficient flow controlhence, marine butterfly valves are typically made from materials such as bronze, stainless steel, or other corrosion-resistant alloys

compliance and certification**: ensure the selected valve meets relevant industry standards and certifications for marine applications, such as those from classification societies like dnv, abs, or lloyd’s register

monitoring: periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazards

operation: operate the valve using the designated controls, whether manual or actuated, following established procedures for opening, closing, and adjusting flow rates as needed

resilient seating: many marine butterfly valves feature resilient seating made of materials like epdm or nbr, which offer excellent sealing properties and resistance to wear, corrosion, and chemicalsIndia

₹ 13827

-

Whether you are a startup airline selecting an initial system or an existing airline choosing to replace outdated technology, trawex airline reservation system provides the features that will allow you to lead your marketcom/airline-reservation-systemit enhances customer service and operational efficiency, adapting to market changes and maximizing revenuefor more details, please visit our website: https://wwwinstantly react to competitive market conditions with intuitive access to all key parameters including fares and inventory

Bangalore (Karnataka)

-

It is always advised to replace the screen from an authorized and experienced technician to avoid any further damages to motherboard and display cablewhile installation of screen make sure technician fix the screen panel with frame perfectly in order to avoid any further damage at hp laptop screen replacement repair center in pune pimple saudagar

phone:020-26303040 / +91776700004, +91776700005

https://goo

following are the main reasons and screen replacement causesgl/maps/b5pljfgywc5p6y53a

hp laptop screen repair replacement center pune pimple saudagar cost may vary

screen flickering repair

screen freeze fix

screen broken external monitor bios / damaged

black spot on screen

white lines on screen

internal damaged by accidental

liquid damageat the time of replacing the screen at hp hp laptop screen replcement center pune pimple saudagar, you must confirm right resolution and warranty assistance3" hp laptop screen replacement pune pimple saudagar

laptop store pune – pimple saudagar

512, fourtuna building,shivar chowk,

opp rainbow plaza/mc donalds,

pimple saudagar,

pune, maharashtra – 411027additionally, it is advised to check for any dot / spot on screen or manufacturer defectPune (Maharashtra)

₹ 5000

-

It is always advised to replace the screen from an authorized and experienced technician to avoid any further damages to motherboard and display cable

following are the main reasons and screen replacement causes

phone: 9545222284,9545222237

https://gooat the time of replacing the screen at hp hp laptop screen replcement center pune viman nagar, you must confirm right resolution and warranty assistance

screen flickering repair

screen freeze fix

screen broken external monitor bios / damaged

black spot on screen

white lines on screen

internal damaged by accidental

liquid damagegl/maps/q3hh5hz4hcnohgkza

hp laptop screen repair replacement center pune viman nagar cost may vary3" hp laptop screen replacement pune viman nagar

laptop store - viman nagar

shop no: 114, sai apex complex, 1st floor,

datta mandir chowk,

viman nagar, pune-411014while installation of screen make sure technician fix the screen panel with frame perfectly in order to avoid any further damage at hp laptop screen replacement repair center in pune viman nagaradditionally, it is advised to check for any dot / spot on screen or manufacturer defectPune (Maharashtra)

₹ 5000