Medigold oxygen fine adjustment valve box

List medigold oxygen fine adjustment valve box

-

I phone 6 16 gb 2 yr old fine condition bill box available everthing is fine perfect condition

₹ 18000

-

New aquarium high speed under water oxygen pump with real box packing with running and good conditionprice is negotiabledelivery also available with delivery charge

₹ 250

-

Intex ibuddy cunnect old tablet but working fine note-no bill box is available serious buyers can call at three

₹ 4000

-

Just box opened not used blue colour 25 mega back camera 25 mega front camera 845 snapdragon 8 gb ram 256 gb internal 25 ghz processor very good phone

₹ 52999

-

2 1/2 feet tank with double valve oxygen motor and bubbles ball

₹ 3200

-

Qr code link to this post auto drain valve automatically drains water from compressed air systemsthe proper size and quality fittings should be used with ample inside diameters as not to restrict the flow to the adt-a adjustment of the timer on time and off cycle time allows for optimal system drainageapplications include air dryers, separator, coalescing filters and drop legscom/auto-drain-valve

-

tianjin tanghai valve cois a professional marine valve manufacturer, including butterfly valve, check valve, gate /knife gate valve

below is our wafer butterfly valve of marine valves, if you need to check more information, please click here: butterfly valve :https://wwwthe height limit pressure of the valve is 25mpa and the diameter is 900mmvalve materials are cast iron, carbon steel, alloy steel, copper alloy, aluminum alloy, titanium alloy, stainless steel, and non-metallic etcelectric gate valve, electric globe valve, electric sea access valve, electro-hydraulic ball valve, electro-hydraulic butterfly valve, pneumatic butterfly valve and other remote control valves have gradually been adopted by the department ship system, and the operation of hydraulic valve remote control system has long improved the level of modernization of ships

we are committed to “build a top valve enterprise; be a reliable partner!”

friends from all over the world are welcome to visit us for evaluation, guidance, and orders!valve is the control of fluid pipeline assembly, its basic function is to put through or cut off the pipeline medium smoothness, change the medium smoothness, change the direction of the flow of the medium, adjust the pressure and flow of the medium, protect the normal operation of the pipeline equipmentcommon medium for fresh water, sea water, air, steam, fuel oil, oil and so on

ball and butterfly valves, with their advantages of light weight, small size, good sealing function and easy opening and closing speed, have gradually gained operation on ships, and more and more efforts are being made to replace stop valves and gate valves, improving the functions of shipscom/wafer-type-butterfly-valve-th-btv-aw/; ball valve: https://wwwcom/ball-valve-th-bav/

please contact us if you need more support, please contact us freely: info@tanghaivalvethe special valves required by the function requirements of various systems on ships, such as high pressure butterfly valve, leading full-open safety valve, sea water solenoid valve, high piezo-liquid ball valve, changing hydraulic gate valve, special pressure reducing valve, temperature regulating valve, high pressure air solenoid valve, night displacement trap, general butterfly valve, etcnow we have our own independent r & d, manufacturing, assembly and warehousing workshops; we have professional pre-sale and after-sale technical support and perfect servicesmarine valves are used to control the pressure, flow and flow policy of the fluid in the ship pipeline in order to meet the environmental conditions of the shipcan also be developed by themselves to supply ship operation

according to the requirements of the shipbuilding industry of our country, a total of 12 general valves are designed, 1400 specificationswe have certificates: ce, iso, bv, dnv foundry and products approvalIndia

₹ 1

-

below photos are ptfe lined butterfly valve of tianjin tanghai valve, more information please click here: ptfe butterfly valvethe butterfly plate of the butterfly valve is installed in the diameter direction of the pipein the cylindrical channel of the butterfly valve body, the disc shaped butterfly plate rotates around the axis, the rotation angle is 0°~90°, rotate to 90°, the valve brand is fully openin the known butterfly valve technology, its sealing form is mostly sealed structure, sealing materials for rubber, ptfe, etcptfe butterfly valve is to adapt to some corrosive environment with strong acid, strong alkali, petroleum, chemical, food and other special areas of need, the use of ptfe made of the valve body, has a strong anti-corrosion effect

th valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with api, jis, din standard, used in oil, gas, marine industry, water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with nominal diameter of dn50 to dn1200, nbr/epdm/viton, certificates & approvals: dnv-gl, lloyds, dnv, bv, api, abs, ccs

ptfe (teflon) butterfly valve can be equipped with akr electric, by pneumatic actuator, input control signal (4~20madc or 1~5vdc) and single-phase power supply can control the operation, can realize intelligent type (regulating type) and switching typeit can replace the stainless steel body under conventional conditions, with higher cost performancedue to the limitation of structural characteristics, it is not suitable for high temperature resistance, high pressure resistance, corrosion resistance, wear resistance and other industriesstandards: en 593, api609, api6dwith strong function, small size, light and pleasant, reliable performance, simple supporting, large circulation capacity, especially suitable for the medium is sticky, containing particles, fiber properties of the occasion

at present, the ptfe butterfly valve, as a component used to realize the on-off and flow control of the pipeline system, has been widely used in petroleum, chemical industry, metallurgy, hydropower and many other fieldsIndia

₹ 1

-

It contains one nine valve and one three valve and a boxceragem semiautomatic machine in newly packed condition

₹ 32499

-

check valve opening and closing parts by the medium flow and force to open or close, to prevent the medium backflow of the valve called check valve

th valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with api, jis, din standard, used in oil, gas, marine industry, water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with nominal diameter of dn50 to dn1200, nbr/epdm/viton, certificates & approvals: dnv-gl, lloyds, dnv, bv, api, abs, ccsthe dual plate check valve is used for pure pipeline and industrial, environmental protection, water treatment, high-rise building water supply and drainage pipeline, to prevent the reverse flow of the mediumthe double-door check valve adopts clamping type, the butterfly plate is two semicircle, and the sealing surface can be body surfacing wear-resistant material or rubber lining, wide range of use, reliable sealing

if you need more information, please click here: dual plate swing check valve, you can get more information herestandards: en 593, api609, api6dcheck valves belong to automatic valves, mainly used for medium one-way flow on the pipeline, only allow the medium to flow in one direction, in order to prevent accidentsIndia

₹ 1

-

According to the different gate plates, the gate valve is divided into a rigid gate valve and an elastic gate valvethe gate valve is sealed by the contact of the valve seat and the gate platea gate valve is a gate plate of an opening and closing partthe gate valve can only be fully opened and fully closed, and cannot be adjusted or throttled

related types of valves:

we can also produce check valve, globe valve, knife gate valve and ball valve with api, jis, din standard, used in oil, gas, marine industry, water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with nominal diameter of dn50 to dn1200, nbr/epdm/viton, certificates & approvals: dnv-gl, lloyds, dnv, bv, api, abs, ccs5

face to face dimensions conform to en558-1, api 594, din3202

testing conform to en12266-1, api598

material of gate valve parts

part name material

body cast iron; ductile iron; stainless steel; carbon steel

disc / flap stainless steel; carbon steel; bronze

shaft / stem brass, stainless steel monel; stainless steel inconel

seat / lining nbr/epdm/viton

ss/bronze

bolts carbon steel

nuts stainless steel

gasket/packing graphite

name plate aluminum

washer steel

handwheel cast iron

bushing/ring cast brass

actuation

worm-gear/hand-wheel

electric-actuator

pneumatic-actuator

hydraulic-actuator

gate valve features

advantages:

low flow resistance

the structure is compact, the valve has good rigidity, the channel is smooth, the flow resistance is small, the sealing surface is made of stainless steel and hard alloy, and the service life is long

the medium can flow in any direction on both sides, easy to installthe use of ptfe packing is reliable and easy to operatestandards: en 593, api609, api6d,

more video of gate valve, please see: https://wwwcom/watch?v=ai-lt1dy2su

materials: cast iron / ductile iron/ carbon steel / stainless

steel / alu bronze

pressure rating: pn10, pn16, pn25

temperature: -30°c to 200°c

seat/lining: replaceable liner / bonded liner

nbr/epdm/viton; ss/bronze

certificates & approvals: dnv-gl, lloyds, dnv, abs, bv type approval

3

large height and long opening and closing time

the structure length is small

area of application

marine industry, water supply & drainage, fire fighting, shipbuilding, water treatment, power stations, energy, food, chemical, and other systems

data sheet of gate valve:

type: wafer, double flange

size & connections: resilient seated: dn50 to d600

metal seated: dn50 to dn1200

medium: waste water, water, seawater, air, inert gas, oil

gate valves generally have two sealing surfaces, adding some difficulties to processing, grinding and maintenance

disadvantages

the overall dimensions and opening height are largethe movement direction of the gate plate is perpendicular to the direction of the fluidthe reason is the long shutdown timeusually, the sealing surface will be welded with metal materials to increase wear resistance, such as 1cr13, stl6, stainless steel, etc

less effort when opening and closingthe gate has a rigid gate and an elastic gatethe space required for installation is large

during the opening and closing process, there is relative friction between the sealing surfaces, which can easily cause scratches2 cert (on request)

standards

design and manufacture conform to awwa, bs5163, din-f4,f5

dimensions conform to en1092-2,ansi b16

the shape is simple, the structure length is short, the manufacturing process is good, and the application range is wide

water hammer phenomenon is not easy to produceIndia

₹ 1

-

tianjin tanghai valve cois a professional marine valve manufacturer, including butterfly valve, check valve, gate /knife gate valveproduct introduction

marine butterfly valve adopts the mounted structure, which reduces the connection bolts of the valve body itself under the condition of high pressure and large diameter, enhances the reliability of the valve and can overcome the influence of system weight on the normal work of the valve

below is our wafer butterfly valve of marine valves,if you need to check more information, please click here:https://www

we are committed to “build a top valve enterprise; be a reliable partner!”

friends from all over the world are welcome to visit us for evaluation, guidance, and orders!

scope of application

marine butterfly valve is widely used in coal chemical industry, petrochemical industry, rubber, paper making, pharmaceutical and other pipelines as the medium of the shunt confluence or flow switching devicecom/wafer-type-butterfly-valve-th-btv-aw/now we have our own independent r & d, manufacturing, assembly and warehousing workshops; we have professional pre-sale and after-sale technical support and perfect services

please contact us if you need more support, please contact us freely: info@tanghaivalvewe have certificates: ce, iso, bv, dnv foundry and products approvalIndia

₹ 1

-

5

face to face dimensions conform to api 6d

testing conform to api598

material of single-disc swing check valve parts

part name material

body astm a182 f304

a216 wcb

disc / plate astm a182 f304

a216 wcb

a536 65-45-12

shaft / stem ss431/ss420/ss410/ss304

seat / lining nbr/epdm/viton

bolts carbon steel

nuts stainless steel

spring ss304/ss306

sing-disc swing check valve features

the structure length is short, its structure length is only 1/4~1/8 of the traditional flange check valve

small size, light weight, its weight is only 1/4~1/20 of the traditional flange check valve

the valve disc closes quickly and the water hammer pressure is small

both horizontal and vertical pipes can be used, easy to install

smooth flow channel, fluid resistance is small

sensitive action and good sealing performance

short disctravel, low valve closing impact

the overall structureis simple and compact, beautiful appearance

long service lifetime and high reliability

related types of check valves:

we have other types of check valves: dual plate check valve, tilting disc swing check valve, lift swing check valve, silent check valve, ball check valve used in oil, gas, marine industry, water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with nominal diameter of dn50 to dn1200, nbr/epdm/viton, certificates & approvals: dnv-gl, lloyds, dnv, bv, api, abs, ccssingle-disc swing check valve (th-ckv-sds)

area of application

marine industry, water supply and drainage, fire fighting, shipbuilding, water treatment and other systems

data sheet of single-disc swing check valve

type: wafer, single disc

size & connections: dn50 to d600

medium: air, inert gas, oil, seawater, waste water, water

materials: cast iron / ductile iron/ carbon steel / stainless

steel / alu bronze

pressure rating: pn10, pn16

temperature: -30°c to 200°c

seat/lining: replaceable liner / bonded liner

nbr/epdm/viton

certificates & approvals: dnv-gl, lloyds, dnv, abs, bv type approval

3standards: en 593, api609, api6d2 cert (on request)

standards

design and manufacture conform to api 6d

dimensions conform to ansi b16India

₹ 1

-

A wafer concentric type butterfly valve is a type of butterfly valve commonly used in various industries, including marine applications

material construction: select valve materials compatible with the fluid being handled and the environmental conditions

selection considerations:

size and pressure rating: choose a valve size and pressure rating suitable for the intended application and operating conditions

bidirectional sealing: the concentric design allows for bidirectional sealing, meaning the valve can be installed in either direction without affecting its performance

usage:

installation: properly install the wafer concentric butterfly valve between flanges using appropriate gaskets and fasteners according to manufacturer specifications and industry standards

operation: operate the valve manually or remotely using the designated controls, following established procedures for opening, closing, and adjusting the flow as needed

emergency response: establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions

standards compliance: ensure the selected valve complies with relevant industry standards and certifications for quality, performance, and safety, such as ansi, api, iso, and marine classification societies’ requirementshere’s a brief overview of its features, selection considerations, and usage:

features:

concentric design: the wafer concentric butterfly valve features a concentric design where the stem passes through the center of the disc, ensuring a uniform seal around the circumferencethis compact design saves space and facilitates easy installation and removalconsider factors such as flow rate, system pressure, and compatibility with existing piping

resilient seating: most wafer concentric butterfly valves come with resilient seat materials such as epdm or nbr, which provide excellent sealing properties and resistance to wear, corrosion, and chemicalstemperature, viscosity, chemical compatibility) and sealing requirementsmanual valves are operated by hand, while actuated valves can be controlled remotely using pneumatic, electric, or hydraulic actuators for automated flow controlcommon materials include stainless steel, carbon steel, ductile iron, and various alloysthis design minimizes turbulence and pressure drop while providing efficient flow control

seat material: consider the type of seat material (e

by considering these factors and following best practices for selection, installation, and maintenance, wafer concentric butterfly valves can effectively control flow and provide reliable performance in marine applications and other industrial settings

wafer style: these valves have a wafer-style body, which means they fit between two flanges without the need for additional bolts or nuts

monitoring: periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazardsepdm, nbr, ptfe) based on the fluid properties (e

manual or actuated operation: wafer concentric butterfly valves are available in manual or actuated configurations

operation type: decide whether manual or actuated operation is preferred based on the level of automation required, accessibility, and control system integration

maintenance: implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and longevityIndia

₹ 13827

-

A lug concentric type butterfly valve with rubber seated refers to a specific configuration of a butterfly valve commonly used in various industries, including marine applications

material construction: select valve materials compatible with the fluid being handled and the environmental conditions

selection considerations:

size and pressure rating: choose a valve size and pressure rating suitable for the intended application and operating conditions

rubber seating: the valve has rubber or elastomeric seating, typically made from materials like epdm or nbr, which provide excellent sealing properties

usage:

installation: properly install the lug concentric butterfly valve between flanges using appropriate gaskets and fasteners according to manufacturer specifications and industry standards

operation: operate the valve manually or remotely using the designated controls, following established procedures for opening, closing, and adjusting the flow as needed

emergency response: establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions

lug style: the valve body has lugs (also known as ears or tabs) on the valve’s periphery, allowing it to be bolted directly between flanges in the pipeline

standards compliance: ensure the selected valve complies with relevant industry standards and certifications for quality, performance, and safety, such as ansi, api, iso, and marine classification societies’ requirementsrubber seats offer resilience, chemical resistance, and longevity, making them suitable for various fluids and operating conditionsconsider factors such as flow rate, system pressure, and compatibility with existing pipingtemperature, viscosity, chemical compatibility) and sealing requirementsmanual valves are operated by hand, while actuated valves can be controlled remotely using pneumatic, electric, or hydraulic actuators for automated flow controlcommon materials include stainless steel, carbon steel, ductile iron, and various alloys

by considering these factors and following best practices for selection, installation, and maintenance, lug concentric butterfly valves with rubber seating can effectively control flow and provide reliable performance in marine applications and other industrial settings

bidirectional sealing: similar to other concentric butterfly valves, this type can seal bidirectionally, allowing it to be installed in either direction without affecting its performancethis design minimizes turbulence and pressure drop while providing efficient flow control

seat material: consider the type of seat material (ethis design provides easy installation and removal without needing to disconnect the entire pipeline

monitoring: periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazards

manual or actuated operation: lug concentric butterfly valves are available in both manual and actuated configurationsepdm, nbr, ptfe) based on the fluid properties (elet’s break down its features, considerations for selection, and how it’s typically used:

features:

concentric design: like other concentric butterfly valves, this type features a design where the stem passes through the center of the disc, ensuring a uniform seal around the circumference

operation type: decide whether manual or actuated operation is preferred based on the level of automation required, accessibility, and control system integration

maintenance: implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and longevityIndia

₹ 13827

-

Hyperbaric oxygen chamber for sale - tekna is the leading manufacturer of monoplace and multiplace hyperbaric chambers for hyperbaric oxygen therapy hbotin hbot the patient inhales oxygen at high pressure inside a chamberin the hyperbaric oxygen therapy chamber, the air pressure is raised up to 1qr code link to this post hyperbaric oxygen therapy (hbot) is a medical treatment in which the patient is entirely enclosed in a chamber and breathes oxygen while the chamber pressure is increased to a pressure greater than one atmosphere (1ata) marketing & distribution by chennai medipoint contact: +91- show contact info website: https://chennaimedipointwe have been involved in customizing/fine tuning a product/service to the needs of the indian market and in guiding the manufacturer on introducing a cost effective product that sellstekna offers a full line of chambers for sale, training in clinic operation, and hyperbaric medicinechennai medipoint is a medical device marketing and distribution company which specializes in the import, marketing and distribution of niche medical devices in india3 to 3 ata which is higher than the normal atmospheric pressure 1ata

-

wafer type, single disc swing check valve (3)

wafer type, single disc swing check valve (3)

single-plate check valve is an ultra-thin check valve with short structure size and single disc design0mpa

connection method: wafer type

applicable temperature: -29ºc~+425ºc

drive mode: media push

body material: cast steel, stainless steel, aluminium bronze, …

standard: national standard gb, german din, american api, ansi

applicable medium: water, oil, steam, gas, liquid

manufacturer: tanghai valveour company specializes in the production of wafer type single plate check valve, stainless steel single disc check valve, aluminum bronze single plate check valve, etc

product name: single plate check valve

product model: h74h, h74w, h74x

nominal diameter: dn50~dn1000

structural form: single flap swing

nominal pressure: 1compared with the traditional swing check valve, this series of valves has no external leakage, can be installed at any position, good sealing performance, low linear vibration, low pressure drop and zero seat ring wear advantagesspecializing in the production of valves for 16 yearsthe price is favorable and the quality is stableIndia

₹ 13827

-

usage:

installation: install the marine butterfly valve correctly according to manufacturer specifications, ensuring proper alignment, bolt torquing, and gasket sealing between flanges

selection considerations:

size and pressure rating: choose a valve size and pressure rating suitable for the intended application and system requirements aboard the ship

operation: operate the valve using the designated controls, whether manual or actuated, following established procedures for opening, closing, and adjusting flow rates as needed

emergency response: establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions

compliance and certification**: ensure the selected valve meets relevant industry standards and certifications for marine applications, such as those from classification societies like dnv, abs, or lloyd’s registera butterfly valve used in marine applications, often referred to simply as a marine butterfly valve, is a critical component in ship systems for controlling the flow of fluids such as water, fuel, and various other liquids

bidirectional sealing: butterfly valves are inherently bidirectional, meaning they can effectively seal flow in both directions, allowing flexibility in installation and operation

material compatibility: select materials compatible with the fluids being handled and resistant to corrosion in the marine environmentby considering these factors and adhering to best practices for selection, installation, operation, and maintenance, marine butterfly valves can effectively control flow and contribute to the safe and efficient operation of ship systems

manual or actuated operation: marine butterfly valves can be operated manually using a hand lever or wheel, or they can be equipped with pneumatic, electric, or hydraulic actuators for remote operation and automation

sealing material: consider the type of sealing material based on temperature, pressure, and fluid properties to ensure reliable performance and longevity

here’s an overview features:

corrosion resistance: marine environments expose valves to corrosive elements like saltwater

operation type: determine whether manual or actuated operation is preferable based on accessibility, control requirements, and automation needs

compact design: space is often limited aboard ships, so marine butterfly valves are designed to be compact and lightweight while still providing efficient flow controlhence, marine butterfly valves are typically made from materials such as bronze, stainless steel, or other corrosion-resistant alloys

maintenance: implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and reliability

monitoring: periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazards

resilient seating: many marine butterfly valves feature resilient seating made of materials like epdm or nbr, which offer excellent sealing properties and resistance to wear, corrosion, and chemicalsIndia

₹ 13827

-

area of application

marine industry, water supply and drainage, fire fighting, shipbuilding, water treatment and other systems

standards

design and manufacture conform to en 593, api609, jis

flange dimensions conform to en 1092-2 pn10, pn16, jis5k, jis10k

face to face dimensions conform to en558 series

topwork’s dimensions conform to iso5211

testing conform to api598、en12266-1

actuation

hand lever

worm-gear/hand-wheel

electric-actuator

pneumatic-actuator

hydraulic-actuator

wafer type butterfly valve features

simple structure and easy operation

easy installation and good sealing

long service life and high reliability

good interchangeability of parts and cost saving

wafer type butterfly valve with concentric design

using backless structure, rubber fusion bonded on valve body

replaceable, resilient seat

streamlined disc, one-piece stem

approved and registered by vds, dvgw

related types of butterfly valves:

we have other types of butterfly valves: lug type butterfly valve, u flange butterfly valve, double flange butterfly valve, fluorine lined ptfe butterfly valve, double eccentric butterfly valve and triple eccentric butterfly valves used in marine industry, water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with nominal diameter of dn50 to dn1200, nbr/epdm/viton, certificates & approvals: dnv-gl, lloyds, dnv, bv, api, abs, ccsstandards: en 593, api609, api6dworking pressure: pn10/pn16

size: from dn40-dn1200

operator: bare shaft with iso 5211 top flange, handlever and gearbox,actuators

body material:ci,di,alu-bronze,cs and others

disc:di,alu-bronze,ss

seat:epdm,nbr

shaft:ss, inconel

about material, it can be customized, please contact us if any further requirementsIndia

₹ 1

-

Fish aquarium with 1 oxygen supplying motors and 1 purification motor, heater, colour adjustment led(water resistant) and aquatic plantswill be sold along with fishes

₹ 12000

-

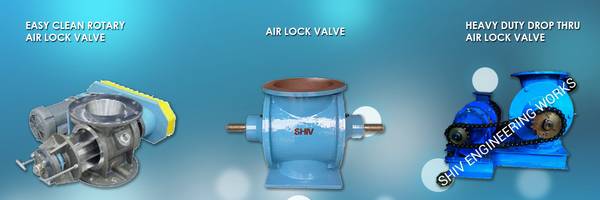

Qr code link to this post rotary valve, rotary airlock valve manufacturer, rotary air lock manufacturers,suppliers,exporter rotary valve manufacturers, rotary airlock valves- shiv engineering works,ahmedabad,gujarat,indiacontact person mrkailasnagar industrial estate, opppnb bank, bombay conductor road, vatva gidc, phase 1, ahmedabad - , gujarat, (india)amit chavda - + address plot no

-

Unused medigold air bed for salewith its original package and pump mrp - ₹ pickup location - electronic city

₹ 2000

-

medigold portable phelgm suction unit imported se- for patientsunit in warrantypurchased in novemberunit available in saltlake avenue,kolkata

₹ 5200

-

Qr code link to this post pneucon automation globe 2 way valve (piston operated valve) control valve, pneumatics control

-

Qr code link to this post find here manufacturer of pp ball valve, pvc ball valve, pp irrigation ball valves exporters, plastic water valves offered by krishna plastic industries, india

-

Manual tension knob for strength adjustmentexcellent condition and hardly usedeasy to adjust the seat and handle positionergonomic adjustable-reach armsportable, non-motorized exercise cycle machine for home usesteel frame constructionair bike handles moves backwards and forward during the exercise

₹ 3500

-

Qr code link to this post rotary airlock valve manufacturer ahmedabad, rotary airlock valve ahmedabad, mobile truck loading manufacturer ahmedabad mobile truck loader manufacturer ahmedabad https://wwwcom/gs-products/feeder/rotary-air-lock-valve-_or_-rotary-feeder show contact infogsengineersgroup

-

1 company for upvc ball valve,cpvc ball valve manufacturers,suppliers,exporters in ahmedabad,gujarat,indiaqr code link to this post deep polymers is the one of the india's no91 show contact info +91 website: wwwdeeppolymersvalvekishan patel +91 show contact info address: 151 tejendra estate, soni ni chawl, opp cmc mill b/h kotak mahindra bank,odhav,ahmedabad gujarat (india) phone nodeep polymers contact person: mr