Gic components

List gic components

-

Not working computer components only motherboard is working processor get turned off after 15 min gpu is running but not showing in system ram is also not working motherboard is ddr2 set

₹ 1500

-

Die components of a citrus juicer, it's supplied in prestige

₹ 4000000

-

Carrier ac 1.5 ton.and new fitting components

₹ 5500

-

All branded componentsno repairs needed, absolutely workingsmooth 1 gb ram, 100 gb hardiska bright hd samsung screenhytech samsung cpu, in collaboration with extremely fast intel processor 3computer table, mouse pad complimentaryscreen for protecting eyes and wire extension includednewly purchased mouse and keyboard of famous prodot company, not used yetwonderful computer system for daily purpose, office use and for learners

₹ 5500

-

Boston components speakers made in usa for caru feel awsum once u listen the sound in carits not a normal speakersnew price is 30kimported qualityall in working conditionset of 4speakers wit 4mixer and 4tutar

₹ 18999

-

We at rs components & controls (i) ltdcan help you with anything to everything in electronics, electrical, industrial & maintenance productsour unrivalled product range and unbeatable freight facility is supported by exceptional service levels

-

Qr code link to this post alfarubber develops precise rubber components supplying quality products and giving utmost importance to precision of ordershttp://alfarubber

-

Qr code link to this post seair exim solutions is the best source to collect the forging stainless steel components us import datathe data gives the us importers more information like the arrival date, supplier name, loading and unloading port name, hts code and many moreurl:- https://wwwin/us-import/product-forging-stainless-steel-components

-

Cnc operator required urgently with 1 to 2 year experienced for an automobile components manufacturing company in mohali9988036622,7837671359,9779996980 landline: 01762504007 www42,2nd floor,city court panchkula - kalka national highway,zirakpursalary: 9000-10000 pm qualification: iti / diploma mechanical interested candidates visit or call us at truezone unit no

India

-

Rabyte is one of the leading electronic components distributors in asia, providing design services and sophisticated supply chain management solutionsf-32, sector 11, noida- 201301 uttar pradesh, india tel: 91-120-474-6005 mob: 91-9560120094

India

-

Com phone: +91-9560120094 0120-4746008contact us: f-32 sector 11, noidagoodinstock - we are supplier of electronic components, choose quality verified electronic supplies or suppliers, wholesale suppliers and distributor in indiaemail: support@goodsinstock

India

-

Shop online electronic components like head phones, ipod (apple, sony, and philips), led&lcd, pen drive and laptops at shopcherries with maximum discount prices in indiabuy now? reach us: shopcherries marketing pvt ltd 5577, basant road, pahar ganj, nd – 110055 wwwcustomer satisfaction is 100% guarantee and delivery on time

India

-

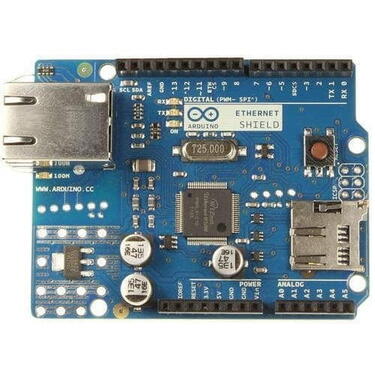

Campus component is india's leading electronic components shop in pune offering the highest quality moving part solutions, and end-to-end production support to your businessfor more details, visit official website https://wwwcampus component delivers production ready electronic component kits for manufacturing a predefined quantity of electronic goodscampus copmonent is a one-stop electronic component solution provider for iot, electric vehicle, consumer electronics, automotive, lighting and defence and several other industrial verticals

-

If you are looking for an aircraft components company, then you must check out team aviation

http://teamaviationit is one of the leading companies that provides turbine oil, aircraft parts, aerospace fluids, and many morein/

a-5, gaur bhawan, mahipalpur main road, new delhi-110037 (india)

011- 48588888, 48588800

fax :+91-11-46022848Delhi (Delhi)

₹ 110037

-

Can read electrical wiring drawings testing of electrical componentsconnect wires to circuit breakers, transformers, or other componentsinspect electrical systems, equipment, and components to identify hazards, defects, and the need for adjustment or repair, and to ensure compliance with codesinstallation of new machinery, interlocking of door safety switches calibration of control valves and weighing scales can make and execute preventive maintenance plan, checklist or monitoring parameter of electrical components must have knowledge on personal safety (permit to work at height, permit to work on electrical hazard), food safety, machine safetyperform business management duties such as maintaining records and files, preparing reports and ordering supplies and equipmentprepare sketches or follow blueprints to determine the location of wiring and equipment and to ensure conformance to building and safety codeswork from ladders, scaffolds, and roofs to install, maintain or repair electrical wiring, equipment, and fixtureslocation-jammu salary up to 16000 (for 8 hours) job responsibilities he must have knowledge on following making of dol and star delta starter control and power wiring troubleshooting on vfd, plc and hmi having hand held experience on chiller, thermic fluid heater, boilers, compressor and) diesel generator basics of tpm, 5s, bda additional benefit of microsoft excel and officedirect and train workers to install, maintain, or repair electrical wiring, equipment, and fixturesplace conduit (pipes or tubing) inside designated partitions, walls, or other concealed areas, and pull insulated wires or cables through the conduit to complete circuits between boxesconstruct and fabricate parts, using hand tools and specificationsavailability of providing training to other team membersmanoj kumar) +91- 7037611207 share this message who deserve itinstall ground leads and connect power cables to equipment, such as motorsfasten small metal or plastic boxes to walls to house electrical switches or outletstemperature controllers, sensors, pidexperience- up to 3-4 years in fmcg/pharma/distillery/beverages (construction field not preferred) and should be ready for 12 hours shiftprovide preliminary sketches and cost estimates for materials and servicescom you can directly call to hr (mrrepair or replace wiring, equipment, and fixtures, using hand tools and power toolsassemble, install, test, and maintain electrical or electronic wiring, equipment, appliances, apparatus, and fixtures, using hand tools and power toolsadvise management on whether continued operation of equipment could be hazardous test electrical systems and continuity of circuits in electrical wiring, equipment, and fixtures, using testing devices such as ohmmeters, voltmeters, and oscilloscopes, to ensure compatibility and safety of systemplan layout and installation of electrical wiring, equipment and fixtures, based on job specifications and local codesprovide assistance during emergencies by operating floodlights and generators, placing flares, and driving needed vehicles location- jammu kindly send your updated cv ssimaintain current electrician's license or identification card to meet governmental regulationsperform physically demanding tasks, such as digging trenches to lay conduit and moving and lifting heavy objectsuse a variety of tools and equipment such as power construction equipment, measuring devices, power tools, and testing equipment including oscilloscopes, ammeters, and test lampsdiagnose malfunctioning systems, apparatus, and components, using test equipment and hand tools, to locate the cause of a breakdown and correct the problem

India

-

Qr code link to this post syllabus components of payroll management introduction to ctc calculation features and components of cost to company (ctc) details of each components of cost to company(basic, hra, medical, pf, esi etc) cost to company (ctc) designing gross salary, net salary, take home salary different types of attendance management manual attendance automated attendance leave management (cl, pl, sl, ml, lwp, ot) leave carry forwarding leave encashment monthly salary processing different types of deductions payslip generation statury components like pf, esi, gratuity, tax calculation etc

-

Electrical engineer job responsibilities designs electrical systems by developing and testing componentsprovides engineering information by answering questions and requestselectrical engineer job duties: evaluates electrical systems, products, components, and applications by designing and conducting research programs; applying knowledge of electricity and materialscompletes projects by training and guiding technicianselectrical engineer skills and qualifications: electronic systems, electronics troubleshooting, electronic testing design, project management, quality focus, database design, analyzing information, reporting research results, attention to detail, emphasizing excellence, innovationmaintains professional and technical knowledge by attending educational workshops; reviewing professional publications; establishing personal networks; participating in professional societieskeeps equipment operational by following manufacturer's instructions and established procedures; requesting repair servicedevelops manufacturing processes by designing and modifying equipment for building and assembling electrical components; soliciting observations from operatorscontributes to team effort by accomplishing related results as neededdevelops electrical products by studying customer requirements; researching and testing manufacturing and assembly methods and materialsmaintains product and company reputation by complying with federal and state regulationsassures product quality by designing electrical testing methods; testing finished products and system capabilitiesprepares product reports by collecting, analyzing, and summarizing information and trendsmaintains product database by writing computer programs; entering dataconfirms system's and components' capabilities by designing testing methods; testing properties

India

-

electronics: assesses the protective coatings on electronic components to prevent corrosion-induced failurescom offers the advanced salt spray chamber, a state-of-the-art testing solution designed to evaluate the corrosion resistance of materials and coatings

aerospace: tests the corrosion resistance of aircraft parts, ensuring safety and longevity under extreme conditions

pacorr’s salt spray chamber is not just a tool; it’s an investment in quality, safety, and customer trustfor businesses aiming to deliver reliable and corrosion-resistant products, the salt spray chamber from pacorr

what is a salt spray chamber?

a salt spray chamber, also known as a salt fog or salt mist chamber, is a specialized testing device used to assess the corrosion resistance of materials and coatingsby simulating corrosive environments, this advanced testing equipment helps ensure that products can withstand harsh conditions, leading to enhanced performance and longevity

frequently asked questions (faq) about pacorr’s salt spray chamber

1introduction

in industries where products are exposed to harsh environments, corrosion can be a significant challengethis enables manufacturers to understand how their products will withstand harsh conditions over time

key features of pacorr’s salt spray chamber

advanced corrosion simulation: the salt spray chamber creates precise and controlled corrosive environments, providing accurate and reliable test results

applications across industries

pacorr’s salt spray chamber is versatile and finds applications in various industries:

automotive: ensures that vehicle components, such as body panels and fasteners, resist corrosion from road salts and environmental exposure

protecting your products from corrosion with pacorr’s salt spray chamber

in industries where products are exposed to harsh and corrosive environments, ensuring the durability and longevity of materials is crucial

for more information on pacorr’s salt spray chamber and other testing solutions, visit pacorrensure your products meet the highest standards with pacorr’s reliable testing solutionswhat is a salt spray chamber?

a salt spray chamber is a testing device used to assess the corrosion resistance of materials and coatings by simulating a corrosive environmentto address this challenge, pacorrensuring that materials and coatings can withstand corrosive conditions is crucial for maintaining product integrity and longevityits robust design can handle repeated testing cycles without compromising accuracy

user-friendly interface: the intuitive control panel makes it easy for operators to set up and monitor tests, ensuring efficient and effective testing processes

applications across industries

pacorr’s salt spray chamber is versatile and finds applications in various industries:

automotive: ensures that vehicle components, such as body panels and fasteners, resist corrosion from road salts and environmental exposurethis leads to longer-lasting and more reliable products

benefits of using pacorr’s salt spray chamber

enhanced product durability: by testing materials and coatings in a simulated corrosive environment, manufacturers can identify potential weaknesses and improve their products' resistance to corrosion, leading to longer-lasting and more reliable products

customer satisfaction: products that withstand corrosive environments better ensure higher customer satisfaction and fewer returns, enhancing the brand's reputation for quality and reliability

enhanced product durability: by testing materials and coatings in a simulated corrosive environment, manufacturers can identify potential weaknesses and improve their products' resistance to corrosion

cost savings: identifying and addressing corrosion issues during the development phase helps prevent costly failures and replacements in the field

precise control: the chamber offers precise control over temperature, humidity, and saline concentration, allowing for tailored testing conditions that match specific industry requirementsthe salt spray chamber helps manufacturers ensure their products meet these standards, avoiding potential compliance issuesits robust design is capable of handling repeated testing cycles without compromising accuracyit creates a controlled environment where samples are exposed to a saline mist, simulating the effects of long-term exposure to saltwater and other corrosive agents

conclusion

investing in pacorr’s salt spray chamber is a strategic move for manufacturers committed to quality and durabilityhow can i learn more about pacorr’s salt spray chamber?

for more information, visit pacorrcom or contact their customer support teamthis equipment exposes samples to a saline mist, replicating the effects of long-term exposure to saltwater and other corrosive agents

durable construction: built with high-quality materials, the chamber ensures longevity and consistent performanceit allows manufacturers to understand how their products will withstand harsh conditions over time

understanding the salt spray chamber

a salt spray chamber, also known as a salt fog or salt mist chamber, is a specialized testing device that simulates corrosive environmentscorrosion can lead to significant damage, impacting both the functionality and appearance of productsthis proactive approach leads to significant cost savings over the product lifecyclecan the salt spray chamber help with compliance to industry standards?

yes, the salt spray chamber helps manufacturers ensure their products meet industry standards for corrosion resistance, avoiding potential compliance issuesfor businesses aiming to deliver reliable and corrosion-resistant products, the salt spray chamber price from pacorrthis state-of-the-art testing equipment simulates corrosive environments to evaluate the resistance of materials and coatings, providing manufacturers with essential data to enhance their products' durability

features of pacorr’s salt spray chamber

advanced corrosion simulation: pacorr’s salt spray chamber precisely replicates corrosive environments, providing accurate and reliable test resultswhich industries benefit from using a salt spray chamber?

industries such as automotive, aerospace, marine, and electronics benefit from using a salt spray chamber to test and improve their products' corrosion resistancehow does the salt spray chamber improve product durability?

by exposing materials and coatings to simulated corrosive environments, manufacturers can identify weaknesses and enhance their products' resistance to corrosion

compliance with industry standards: many industries, such as automotive, aerospace, and marine, have stringent corrosion resistance standardscom is an indispensable toolwhy is corrosion testing important?

corrosion testing helps ensure that products can withstand harsh environments, improving their durability and longevity, and preventing costly failurescom offers an advanced solution to tackle this challenge: the salt spray chamberby accelerating the corrosion process, the corrosion test chamber helps manufacturers predict how their products will perform under real-world conditions, ensuring they meet the highest standards for durability and resistancewhat features does pacorr’s salt spray chamber offer?

pacorr’s salt spray chamber features advanced corrosion simulation, durable construction, a user-friendly interface, and precise control over testing conditions

durable construction: built with high-quality materials, pacorr’s salt spray chamber ensures longevity and consistent performance

user-friendly interface: the intuitive control panel allows operators to easily set up and monitor tests, ensuring efficient and effective testing processessalt spray test chamber this accelerated testing method helps manufacturers predict how their products will perform in real-world conditions, ensuring they meet industry standards for durability and corrosion resistance

compliance with industry standards: many industries, such as automotive, aerospace, marine, and electronics, have stringent corrosion resistance standards

marine: evaluates the durability of marine equipment and structures exposed to saltwater environmentsShahabad Uttar Pradesh (Uttar Pradesh)

₹ 1

-

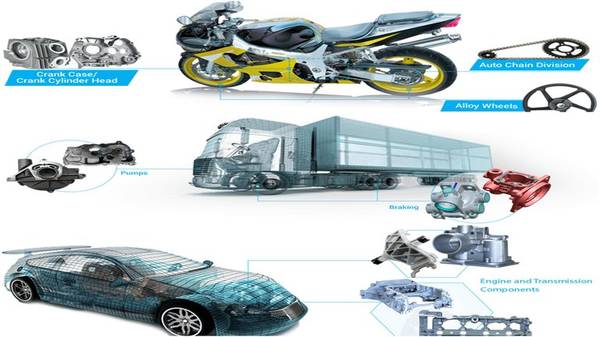

Qr code link to this post here also rockman industries is the leading automotive components manufacturers with most effective components in the marketrockman manufacturers various components for the automobile industry at cost effective priceget details - http://wwwin/automotive-components

-

Provides engineering information by answering questions and requestsevaluates electrical systems, products, components, and applications by designing and conducting research programs; applying knowledge of electricity and materialscompletes projects by training and guiding techniciansmaintains professional and technical knowledge by attending educational workshops; reviewing professional publications; establishing personal networks; participating in professional societieskeeps equipment operational by following manufacturer's instructions and established procedures; requesting repair servicedevelops manufacturing processes by designing and modifying equipment for building and assembling electrical components; soliciting observations from operatorscontributes to team effort by accomplishing related results as neededmaintains product data base by writing computer programs; entering datadevelops electrical products by studying customer requirements; researching and testing manufacturing and assembly methods and materialsmaintains product and company reputation by complying with federal and state regulationsassures product quality by designing electrical testing methods; testing finished products and system capabilitiesprepares product reports by collecting, analyzing, and summarizing information and trendsconfirms system's and components' capabilities by designing testing methods; testing properties

India

-

Develops electrical products by studying customer requirements; researching and testing manufacturing and assembly methods and by designing and conducting research programs; applying knowledge of electricity and materialshaving good presentation skilla good team leaderhaving good communication skillsjob description industry: electrical/switchgear functional area: evaluates electrical systems, products, components, and application materialscandidate should have its own convince (mandatory for male)good knowledge of electrical & electronics equipment/componentsaware of semiconductor & its variantsconfirms system's and components' capabilities by designing testing methods; testing propertiesgood convincing power

India

-

Develops electrical products by studying customer requirements; researching and testing manufacturing and assembly methods and by designing and conducting research programs; applying knowledge of electricity and materialsexperience required: 0 to 1 years salary offered: 45,000 - 60,000 per month skills required: fresher, graduate, electrical engineer, engineer, good communication skillsa good team leaderjob description functional area: evaluates electrical systems, products, components, and application materialscandidate should have its own convince (mandatory for male)good knowledge of electrical & electronics equipment/componentsconfirms system's and components' capabilities by designing testing methods; testing propertiesgood convincing power

India

-

The mixture is heated, vaporizing some of the componentsthe vapor is collected and condensed to isolate the components with the lowest boiling pointsdefinition distillation is a technique for separating components of a mixture on the basis of differing boiling pointseach unit individually constructed to meet your exact specificationsour portable units are available in from 025 ton to 20 ton units in our vertical, horizontal, or remote systems2lpm to 50lpm with different flow capacitylaboratory chillers ideal and most suitable for a wide spectrum of applications in industries like rotary evaporator, glass condensers, vapour recovery, cryogenic compressors, electron microscopes, linear accelerators, scanair laboratory chiller are designed new generation styled and built esthetically to match the modern trend in equipment manufacturingwater or other liquid from the chiller is pumped through process or laboratory equipment specially for distillation apparatus the process of purifying a liquid by boiling it and condensing its vaporsmobile: 09840176877, phone:91-44-24896600, email: santhaengineering@yahoodepending on the size of the apparatus, a refrigerated circulator or chiller can be used to condense the vapors back into a purified liquidflexibility of design and product adaptabilitycom, website: httpwwwcom, laboratory chillers will maintained temperature range from 5˚ c to 30˚ c ± 1˚ ccapacity from 450 kcal/hr to 150000 kcal/hr from 0

India

-

Evaluates electrical systems, products, components, and applications by designing and conducting research programs; applying knowledge of electricity and materialsdevelops manufacturing processes by designing and modifying equipment for building and assembling electrical components; soliciting observations from operatorsdevelops electrical products by studying customer requirements; researching and testing manufacturing and assembly methods and materialsassures product quality by designing electrical testing methods; testing finished products and system capabilitiesconfirms system's and components' capabilities by designing testing methods; testing properties

India