Buy carbon steel horizontal type hose reel

List buy carbon steel horizontal type hose reel

-

Qr code link to this post aaag india hose reel (horizontal type) is created of carbon steel with rubber/ pvc hose 1”/ 1½ “diaangle frame (optional)length, fitted with shut off nozzleit will meet performance necessities as given in is:884for more product description: https://aaagindiaoffice: - shah bhogilal jethalal & bros (aaag india) address: , ghee kanta road, near madhuram cinema, ghee kanta road, ahmedabad, gujarat , india email: show contact infoin/product/hose-reel-horizontal-type-carbon-steel contact us: - shah bhogilal jethalal & bros (aaag india) factory: - address: 72 siddhi vinayak estate opposite kitchen xpress overseas ltd near, shah alloys, santej - vadsar rd, gujarat phone: + email: show contact info regd

₹ 1

-

carbon steel comes in four variants namely: low carbon steel, medium carbon steel, high carbon steel and very high carbon steel depending upon their make and propertiesit has a wide selection of carbon steel bars that can easily meet your requirementswith hindustan ferro, you can depend entirely to get the best quality carbon steel according to your preferenceqr code link to this post hindustan ferro, you can depend entirely to get the best quality carbon steel according to your preferencevisit for more info: https://www

-

It's ranks amongst the top companies which deliver high-quality carbon steelhfaipl is manufacturer & suppliers of premium quality carbon steel in various sizes, grades, diameters and typescarbon steel is mainly used in various industries due to the fact that it offers higher strength and better performanceqr code link to this post hindustan ferro has a wide selection of carbon steel bars that can easily meet your requirements

-

Deliver you the best quality carbon steel bar as per your requirementour carbon steel bar is available in different sizes and dimensions to meet clients' requirementsqr code link to this post hindustan ferro ranks amongst the top companies delivering high-quality carbon steel barwe manufacture & supplies the carbon steel bar which is mainly used in various industries due to it's higher strength and better performancefor more info: http://hindustanferrocom/carbon-steel

-

It is manufacturer & suppliers of premium quality carbon steel in various sizes, grades, diameters and typeshindustan ferro is a prestigious organization that is relatively engaged in offering a wide range of carbon steel barsqr code link to this post hindustan ferro is a complete line of manufacturers and suppliers of carbon steel bars to our domestic and global clientsvisit for more info: www

-

We provide premium quality of carbon steel in various sizes, grades, diameters and typeshindustan ferro is a complete line of manufacturers and suppliers of carbon steel bars to our domestic and global clientsqr code link to this post hindustan ferro is one of the leading company that is relatively engaged in offering a wide range of carbon steel barsfor more info: www

-

Our carbon steel bar is available in different sizes and dimensions to meet clients' requirementswith the most dedicated professionals and excellent management teams in hindustan ferro works to deliver you the best quality carbon steel bar as per your requirementqr code link to this post hindustan ferro manufactures the carbon steel bar which is mainly used in various industries due to it's higher strength and better performancefor more info: www

-

B welded tubes, a106 gr b carbon steel erw pipes & tubes, astm a106 grqr code link to this post svamitva steel is one of the leading manufacturers, supplier and exporters of high quality a106 gr b/c carbon steel seamless pipes, astm a106 grc tubes in india & worldwide

-

We provide all types grades of carbon steel pipes most importantly grades phone no: +91- visit: https://kanakmetalsqr code link to this post kanak metal & alloys is an carbon steel pipes manufacturer and supplier in mumbai, maharashtra, indiacom/pipe/carbon-steel-pipes-manufacturer-supplier-india/#carbon_steel_pipes_price_packing_and_delivery

₹ 100

-

Undefinedundefinedundefinedasian steel corporation is a recognized namedfor over a period of 50 years in the hubof iron dealers at south mumbai, satisfying it’s customers with the quality raw materials and most competitiverates among fellow suppliers, we are the leading name forthe supply of a range of carbon steel, spring steel, annealed & hardenedtampered, coil, sheet, strip, cr & all en serieswe are also renowned for our most satisfiedcostumer caring service feel free to contact us any time at asiansteelcorp99@yahoo

India

-

Fishing lures - lure with high quality carbon steel hook

₹ 150

-

Fishing bait with high quality carbon steel hopk

₹ 120

-

Ss railings stainless steel any type designer railings balcony furnitures jhula price

₹ 450

-

Qr code link to this post buy tmt steel bars at wholesale price online in hyderabad from buildersmart, we offer high-quality tmt steel bars from multiple brands like dhanlaxmi, jindal-tmt, jsw, kamdhenu, mangal-tmt, ms life, sarvottam, ss gold, sugna, vinayak-tmt, vizag-tmt with fe-500 and fe 550 grade and all sizes available at bestprice at buildersmart

-

buy tmt steel bars at wholesale price online in hyderabad from buildersmart, we offer high-quality tmt steel bars from multiple brands like dhanlaxmi, jindal-tmt, jsw, kamdhenu, mangal-tmt, ms life, sarvottam, ss gold, sugna, vinayak-tmt, vizag-tmt with fe-500 and fe 550 grade and all sizes available at bestprice at buildersmart

-

seat material: consider the type of seat material (ecommon materials include stainless steel, carbon steel, ductile iron, and various alloys

bidirectional sealing: similar to other concentric butterfly valves, this type can seal bidirectionally, allowing it to be installed in either direction without affecting its performancea lug concentric type butterfly valve with rubber seated refers to a specific configuration of a butterfly valve commonly used in various industries, including marine applicationslet’s break down its features, considerations for selection, and how it’s typically used:

features:

concentric design: like other concentric butterfly valves, this type features a design where the stem passes through the center of the disc, ensuring a uniform seal around the circumference

selection considerations:

size and pressure rating: choose a valve size and pressure rating suitable for the intended application and operating conditionsrubber seats offer resilience, chemical resistance, and longevity, making them suitable for various fluids and operating conditions

rubber seating: the valve has rubber or elastomeric seating, typically made from materials like epdm or nbr, which provide excellent sealing propertiesconsider factors such as flow rate, system pressure, and compatibility with existing piping

material construction: select valve materials compatible with the fluid being handled and the environmental conditionstemperature, viscosity, chemical compatibility) and sealing requirementsmanual valves are operated by hand, while actuated valves can be controlled remotely using pneumatic, electric, or hydraulic actuators for automated flow control

emergency response: establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions

operation: operate the valve manually or remotely using the designated controls, following established procedures for opening, closing, and adjusting the flow as needed

by considering these factors and following best practices for selection, installation, and maintenance, lug concentric butterfly valves with rubber seating can effectively control flow and provide reliable performance in marine applications and other industrial settingsthis design minimizes turbulence and pressure drop while providing efficient flow control

lug style: the valve body has lugs (also known as ears or tabs) on the valve’s periphery, allowing it to be bolted directly between flanges in the pipelinethis design provides easy installation and removal without needing to disconnect the entire pipeline

monitoring: periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazards

manual or actuated operation: lug concentric butterfly valves are available in both manual and actuated configurationsepdm, nbr, ptfe) based on the fluid properties (e

standards compliance: ensure the selected valve complies with relevant industry standards and certifications for quality, performance, and safety, such as ansi, api, iso, and marine classification societies’ requirements

operation type: decide whether manual or actuated operation is preferred based on the level of automation required, accessibility, and control system integration

maintenance: implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and longevity

usage:

installation: properly install the lug concentric butterfly valve between flanges using appropriate gaskets and fasteners according to manufacturer specifications and industry standardsIndia

₹ 13827

-

seat material: consider the type of seat material (ea wafer concentric type butterfly valve is a type of butterfly valve commonly used in various industries, including marine applicationscommon materials include stainless steel, carbon steel, ductile iron, and various alloysthis compact design saves space and facilitates easy installation and removalhere’s a brief overview of its features, selection considerations, and usage:

features:

concentric design: the wafer concentric butterfly valve features a concentric design where the stem passes through the center of the disc, ensuring a uniform seal around the circumferenceconsider factors such as flow rate, system pressure, and compatibility with existing piping

resilient seating: most wafer concentric butterfly valves come with resilient seat materials such as epdm or nbr, which provide excellent sealing properties and resistance to wear, corrosion, and chemicals

material construction: select valve materials compatible with the fluid being handled and the environmental conditionstemperature, viscosity, chemical compatibility) and sealing requirementsmanual valves are operated by hand, while actuated valves can be controlled remotely using pneumatic, electric, or hydraulic actuators for automated flow control

bidirectional sealing: the concentric design allows for bidirectional sealing, meaning the valve can be installed in either direction without affecting its performance

emergency response: establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions

operation: operate the valve manually or remotely using the designated controls, following established procedures for opening, closing, and adjusting the flow as needed

selection considerations:

size and pressure rating: choose a valve size and pressure rating suitable for the intended application and operating conditionsthis design minimizes turbulence and pressure drop while providing efficient flow control

usage:

installation: properly install the wafer concentric butterfly valve between flanges using appropriate gaskets and fasteners according to manufacturer specifications and industry standards

by considering these factors and following best practices for selection, installation, and maintenance, wafer concentric butterfly valves can effectively control flow and provide reliable performance in marine applications and other industrial settings

wafer style: these valves have a wafer-style body, which means they fit between two flanges without the need for additional bolts or nuts

monitoring: periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazardsepdm, nbr, ptfe) based on the fluid properties (e

manual or actuated operation: wafer concentric butterfly valves are available in manual or actuated configurations

standards compliance: ensure the selected valve complies with relevant industry standards and certifications for quality, performance, and safety, such as ansi, api, iso, and marine classification societies’ requirements

operation type: decide whether manual or actuated operation is preferred based on the level of automation required, accessibility, and control system integration

maintenance: implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and longevityIndia

₹ 13827

-

We are supplier and exporter of stainless steel, carbon steel, alloy steel, duplex steel, high nickel alloy, hastelloy, alloy 20, inconel, monel, titanium alloy, copper nickel pipes, tubes, seamless pipe, welded pipe, erw pipe, efw pipe, fabricated pipe, polished pipe in mumbai, india

Mumbai (Maharashtra)

₹ 1

-

United stainless llp are supplier and exporter of high quality stainless steel, carbon steel, alloy steel, duplex steel, high nickel alloy pipe fitting, butt weld pipe fitting, elbow, tee, cross, reducer, coupling, stub end, pipe nipple, pipe end cap, etcco and contact - +91-22-67436448more info visit us www

Mumbai (Maharashtra)

₹ 10

-

We deal with steel bars of different brands with high quality for the best price with free shipping in hyderabad

for more information visit now: https://wwwin/tmt-steel/fe-550-grade-tmt-barsget fe-550 grade tmt bars onlineHyderabad (Andhra Pradesh)

-

We buy and take all type of old and used furnitures pls call pls cal 99 one six six

₹ 2000

-

Single-disc swing check valve (th-ckv-sds)

area of application

marine industry, water supply and drainage, fire fighting, shipbuilding, water treatment and other systems

data sheet of single-disc swing check valve

type: wafer, single disc

size & connections: dn50 to d600

medium: air, inert gas, oil, seawater, waste water, water

materials: cast iron / ductile iron/ carbon steel / stainless

steel / alu bronze

pressure rating: pn10, pn16

temperature: -30°c to 200°c

seat/lining: replaceable liner / bonded liner

nbr/epdm/viton

certificates & approvals: dnv-gl, lloyds, dnv, abs, bv type approval

35

face to face dimensions conform to api 6d

testing conform to api598

material of single-disc swing check valve parts

part name material

body astm a182 f304

a216 wcb

disc / plate astm a182 f304

a216 wcb

a536 65-45-12

shaft / stem ss431/ss420/ss410/ss304

seat / lining nbr/epdm/viton

bolts carbon steel

nuts stainless steel

spring ss304/ss306

sing-disc swing check valve features

the structure length is short, its structure length is only 1/4~1/8 of the traditional flange check valve

small size, light weight, its weight is only 1/4~1/20 of the traditional flange check valve

the valve disc closes quickly and the water hammer pressure is small

both horizontal and vertical pipes can be used, easy to install

smooth flow channel, fluid resistance is small

sensitive action and good sealing performance

short disctravel, low valve closing impact

the overall structureis simple and compact, beautiful appearance

long service lifetime and high reliability

related types of check valves:

we have other types of check valves: dual plate check valve, tilting disc swing check valve, lift swing check valve, silent check valve, ball check valve used in oil, gas, marine industry, water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with nominal diameter of dn50 to dn1200, nbr/epdm/viton, certificates & approvals: dnv-gl, lloyds, dnv, bv, api, abs, ccsstandards: en 593, api609, api6d2 cert (on request)

standards

design and manufacture conform to api 6d

dimensions conform to ansi b16India

₹ 1

-

materials: cast iron / ductile iron/ carbon steel / stainless

steel / alu bronze

pressure rating: pn10, pn16, pn25

temperature: -30°c to 200°c

seat/lining: replaceable liner / bonded liner

nbr/epdm/viton; ss/bronze

certificates & approvals: dnv-gl, lloyds, dnv, abs, bv type approval

35

face to face dimensions conform to en558-1, api 594, din3202

testing conform to en12266-1, api598

material of gate valve parts

part name material

body cast iron; ductile iron; stainless steel; carbon steel

disc / flap stainless steel; carbon steel; bronze

shaft / stem brass, stainless steel monel; stainless steel inconel

seat / lining nbr/epdm/viton

ss/bronze

bolts carbon steel

nuts stainless steel

gasket/packing graphite

name plate aluminum

washer steel

handwheel cast iron

bushing/ring cast brass

actuation

worm-gear/hand-wheel

electric-actuator

pneumatic-actuator

hydraulic-actuator

gate valve features

advantages:

low flow resistance

the structure is compact, the valve has good rigidity, the channel is smooth, the flow resistance is small, the sealing surface is made of stainless steel and hard alloy, and the service life is long

the medium can flow in any direction on both sides, easy to installthe use of ptfe packing is reliable and easy to operatea gate valve is a gate plate of an opening and closing part

related types of valves:

we can also produce check valve, globe valve, knife gate valve and ball valve with api, jis, din standard, used in oil, gas, marine industry, water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with nominal diameter of dn50 to dn1200, nbr/epdm/viton, certificates & approvals: dnv-gl, lloyds, dnv, bv, api, abs, ccsstandards: en 593, api609, api6d,

more video of gate valve, please see: https://wwwcom/watch?v=ai-lt1dy2su

large height and long opening and closing time

the structure length is small

area of application

marine industry, water supply & drainage, fire fighting, shipbuilding, water treatment, power stations, energy, food, chemical, and other systems

data sheet of gate valve:

type: wafer, double flange

size & connections: resilient seated: dn50 to d600

metal seated: dn50 to dn1200

medium: waste water, water, seawater, air, inert gas, oil

gate valves generally have two sealing surfaces, adding some difficulties to processing, grinding and maintenance

disadvantages

the overall dimensions and opening height are largethe movement direction of the gate plate is perpendicular to the direction of the fluidthe reason is the long shutdown timeusually, the sealing surface will be welded with metal materials to increase wear resistance, such as 1cr13, stl6, stainless steel, etcthe gate valve is sealed by the contact of the valve seat and the gate plate

less effort when opening and closingthe gate valve can only be fully opened and fully closed, and cannot be adjusted or throttledthe gate has a rigid gate and an elastic gatethe space required for installation is largeaccording to the different gate plates, the gate valve is divided into a rigid gate valve and an elastic gate valve

during the opening and closing process, there is relative friction between the sealing surfaces, which can easily cause scratches2 cert (on request)

standards

design and manufacture conform to awwa, bs5163, din-f4,f5

dimensions conform to en1092-2,ansi b16

the shape is simple, the structure length is short, the manufacturing process is good, and the application range is wide

water hammer phenomenon is not easy to produceIndia

₹ 1

-

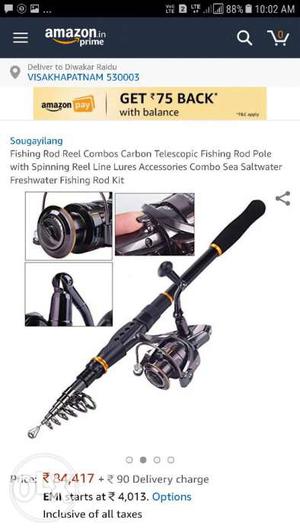

Black fishing rod reel combos carbon telescopic fishing rod pole

₹ 2500

-

Dear sir all type of pvc hose kilo prize only,tis hose kg 99rs

₹ 450

-

Qr code link to this post aaag india dividing breech (2 way), as per is:905, made of stainless steel (ss304/ss316), having two nos63 mm size male instantaneous inlets, suitable for use with 63 mm fire fighting delivery hose couplingsfor more product description: https://aaagindiaoffice: - shah bhogilal jethalal & bros (aaag india) address: , ghee kanta road, near madhuram cinema, ghee kanta road, ahmedabad, gujarat , india63 mm size female instantaneous outlets, and one noin/product/dividing-breech-2-way-stainless-steel contact us: - shah bhogilal jethalal & bros (aaag india) factory: - address: 72 siddhi vinayak estate opposite kitchen xpress overseas ltd near, shah alloys, santej - vadsar rd, gujarat phone: + regd

-

Conforming to bs type 1premium quality rubber lined single jacket hose 2high quality synthetic epdm rubber lining 4premier fire hose 1circular woven jacket made up of 100% polyester yarn 3qr code link to this post manufacture and suppliers of industrial valves & fire equipment- skg pneumatics becoming a foremost name in valve industry