Butterfly

List butterfly

-

The butterfly plate of the butterfly valve is installed in the diameter direction of the pipe

below photos are ptfe lined butterfly valve of tianjin tanghai valve, more information please click here: ptfe butterfly valvein the cylindrical channel of the butterfly valve body, the disc shaped butterfly plate rotates around the axis, the rotation angle is 0°~90°, rotate to 90°, the valve brand is fully openin the known butterfly valve technology, its sealing form is mostly sealed structure, sealing materials for rubber, ptfe, etc

at present, the ptfe butterfly valve, as a component used to realize the on-off and flow control of the pipeline system, has been widely used in petroleum, chemical industry, metallurgy, hydropower and many other fields

ptfe (teflon) butterfly valve can be equipped with akr electric, by pneumatic actuator, input control signal (4~20madc or 1~5vdc) and single-phase power supply can control the operation, can realize intelligent type (regulating type) and switching typeptfe butterfly valve is to adapt to some corrosive environment with strong acid, strong alkali, petroleum, chemical, food and other special areas of need, the use of ptfe made of the valve body, has a strong anti-corrosion effect

th valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with api, jis, din standard, used in oil, gas, marine industry, water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with nominal diameter of dn50 to dn1200, nbr/epdm/viton, certificates & approvals: dnv-gl, lloyds, dnv, bv, api, abs, ccsit can replace the stainless steel body under conventional conditions, with higher cost performancedue to the limitation of structural characteristics, it is not suitable for high temperature resistance, high pressure resistance, corrosion resistance, wear resistance and other industriesstandards: en 593, api609, api6dwith strong function, small size, light and pleasant, reliable performance, simple supporting, large circulation capacity, especially suitable for the medium is sticky, containing particles, fiber properties of the occasionIndia

₹ 1

-

area of application

marine industry, water supply and drainage, fire fighting, shipbuilding, water treatment and other systems

standards

design and manufacture conform to en 593, api609, jis

flange dimensions conform to en 1092-2 pn10, pn16, jis5k, jis10k

face to face dimensions conform to en558 series

topwork’s dimensions conform to iso5211

testing conform to api598、en12266-1

actuation

hand lever

worm-gear/hand-wheel

electric-actuator

pneumatic-actuator

hydraulic-actuator

wafer type butterfly valve features

simple structure and easy operation

easy installation and good sealing

long service life and high reliability

good interchangeability of parts and cost saving

wafer type butterfly valve with concentric design

using backless structure, rubber fusion bonded on valve body

replaceable, resilient seat

streamlined disc, one-piece stem

approved and registered by vds, dvgw

related types of butterfly valves:

we have other types of butterfly valves: lug type butterfly valve, u flange butterfly valve, double flange butterfly valve, fluorine lined ptfe butterfly valve, double eccentric butterfly valve and triple eccentric butterfly valves used in marine industry, water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with nominal diameter of dn50 to dn1200, nbr/epdm/viton, certificates & approvals: dnv-gl, lloyds, dnv, bv, api, abs, ccsstandards: en 593, api609, api6dworking pressure: pn10/pn16

size: from dn40-dn1200

operator: bare shaft with iso 5211 top flange, handlever and gearbox,actuators

body material:ci,di,alu-bronze,cs and others

disc:di,alu-bronze,ss

seat:epdm,nbr

shaft:ss, inconel

about material, it can be customized, please contact us if any further requirementsIndia

₹ 1

-

Hence, marine butterfly valves are typically made from materials such as bronze, stainless steel, or other corrosion-resistant alloysa butterfly valve used in marine applications, often referred to simply as a marine butterfly valve, is a critical component in ship systems for controlling the flow of fluids such as water, fuel, and various other liquids

usage:

installation: install the marine butterfly valve correctly according to manufacturer specifications, ensuring proper alignment, bolt torquing, and gasket sealing between flanges

bidirectional sealing: butterfly valves are inherently bidirectional, meaning they can effectively seal flow in both directions, allowing flexibility in installation and operation

compact design: space is often limited aboard ships, so marine butterfly valves are designed to be compact and lightweight while still providing efficient flow control

resilient seating: many marine butterfly valves feature resilient seating made of materials like epdm or nbr, which offer excellent sealing properties and resistance to wear, corrosion, and chemicalsby considering these factors and adhering to best practices for selection, installation, operation, and maintenance, marine butterfly valves can effectively control flow and contribute to the safe and efficient operation of ship systems

manual or actuated operation: marine butterfly valves can be operated manually using a hand lever or wheel, or they can be equipped with pneumatic, electric, or hydraulic actuators for remote operation and automation

material compatibility: select materials compatible with the fluids being handled and resistant to corrosion in the marine environment

sealing material: consider the type of sealing material based on temperature, pressure, and fluid properties to ensure reliable performance and longevity

emergency response: establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions

selection considerations:

size and pressure rating: choose a valve size and pressure rating suitable for the intended application and system requirements aboard the ship

here’s an overview features:

corrosion resistance: marine environments expose valves to corrosive elements like saltwater

operation type: determine whether manual or actuated operation is preferable based on accessibility, control requirements, and automation needs

compliance and certification**: ensure the selected valve meets relevant industry standards and certifications for marine applications, such as those from classification societies like dnv, abs, or lloyd’s register

maintenance: implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and reliability

monitoring: periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazards

operation: operate the valve using the designated controls, whether manual or actuated, following established procedures for opening, closing, and adjusting flow rates as neededIndia

₹ 13827

-

below is our wafer butterfly valve of marine valves, if you need to check more information, please click here: butterfly valve :https://wwwis a professional marine valve manufacturer, including butterfly valve, check valve, gate /knife gate valveelectric gate valve, electric globe valve, electric sea access valve, electro-hydraulic ball valve, electro-hydraulic butterfly valve, pneumatic butterfly valve and other remote control valves have gradually been adopted by the department ship system, and the operation of hydraulic valve remote control system has long improved the level of modernization of shipsthe special valves required by the function requirements of various systems on ships, such as high pressure butterfly valve, leading full-open safety valve, sea water solenoid valve, high piezo-liquid ball valve, changing hydraulic gate valve, special pressure reducing valve, temperature regulating valve, high pressure air solenoid valve, night displacement trap, general butterfly valve, etc

ball and butterfly valves, with their advantages of light weight, small size, good sealing function and easy opening and closing speed, have gradually gained operation on ships, and more and more efforts are being made to replace stop valves and gate valves, improving the functions of shipsvalve materials are cast iron, carbon steel, alloy steel, copper alloy, aluminum alloy, titanium alloy, stainless steel, and non-metallic etc

we are committed to “build a top valve enterprise; be a reliable partner!”

friends from all over the world are welcome to visit us for evaluation, guidance, and orders!common medium for fresh water, sea water, air, steam, fuel oil, oil and so onthe height limit pressure of the valve is 25mpa and the diameter is 900mmcom/wafer-type-butterfly-valve-th-btv-aw/; ball valve: https://wwwcom/ball-valve-th-bav/

please contact us if you need more support, please contact us freely: info@tanghaivalvenow we have our own independent r & d, manufacturing, assembly and warehousing workshops; we have professional pre-sale and after-sale technical support and perfect servicesvalve is the control of fluid pipeline assembly, its basic function is to put through or cut off the pipeline medium smoothness, change the medium smoothness, change the direction of the flow of the medium, adjust the pressure and flow of the medium, protect the normal operation of the pipeline equipmentmarine valves are used to control the pressure, flow and flow policy of the fluid in the ship pipeline in order to meet the environmental conditions of the shipcan also be developed by themselves to supply ship operation

according to the requirements of the shipbuilding industry of our country, a total of 12 general valves are designed, 1400 specifications

tianjin tanghai valve cowe have certificates: ce, iso, bv, dnv foundry and products approvalIndia

₹ 1

-

A wafer concentric type butterfly valve is a type of butterfly valve commonly used in various industries, including marine applications

manual or actuated operation: wafer concentric butterfly valves are available in manual or actuated configurations

usage:

installation: properly install the wafer concentric butterfly valve between flanges using appropriate gaskets and fasteners according to manufacturer specifications and industry standards

resilient seating: most wafer concentric butterfly valves come with resilient seat materials such as epdm or nbr, which provide excellent sealing properties and resistance to wear, corrosion, and chemicals

by considering these factors and following best practices for selection, installation, and maintenance, wafer concentric butterfly valves can effectively control flow and provide reliable performance in marine applications and other industrial settingshere’s a brief overview of its features, selection considerations, and usage:

features:

concentric design: the wafer concentric butterfly valve features a concentric design where the stem passes through the center of the disc, ensuring a uniform seal around the circumferencethis compact design saves space and facilitates easy installation and removalconsider factors such as flow rate, system pressure, and compatibility with existing piping

material construction: select valve materials compatible with the fluid being handled and the environmental conditionstemperature, viscosity, chemical compatibility) and sealing requirementsmanual valves are operated by hand, while actuated valves can be controlled remotely using pneumatic, electric, or hydraulic actuators for automated flow controlcommon materials include stainless steel, carbon steel, ductile iron, and various alloys

bidirectional sealing: the concentric design allows for bidirectional sealing, meaning the valve can be installed in either direction without affecting its performance

emergency response: establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions

operation: operate the valve manually or remotely using the designated controls, following established procedures for opening, closing, and adjusting the flow as needed

selection considerations:

size and pressure rating: choose a valve size and pressure rating suitable for the intended application and operating conditionsthis design minimizes turbulence and pressure drop while providing efficient flow control

seat material: consider the type of seat material (e

wafer style: these valves have a wafer-style body, which means they fit between two flanges without the need for additional bolts or nuts

monitoring: periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazardsepdm, nbr, ptfe) based on the fluid properties (e

standards compliance: ensure the selected valve complies with relevant industry standards and certifications for quality, performance, and safety, such as ansi, api, iso, and marine classification societies’ requirements

operation type: decide whether manual or actuated operation is preferred based on the level of automation required, accessibility, and control system integration

maintenance: implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and longevityIndia

₹ 13827

-

A lug concentric type butterfly valve with rubber seated refers to a specific configuration of a butterfly valve commonly used in various industries, including marine applications

manual or actuated operation: lug concentric butterfly valves are available in both manual and actuated configurations

usage:

installation: properly install the lug concentric butterfly valve between flanges using appropriate gaskets and fasteners according to manufacturer specifications and industry standards

bidirectional sealing: similar to other concentric butterfly valves, this type can seal bidirectionally, allowing it to be installed in either direction without affecting its performance

by considering these factors and following best practices for selection, installation, and maintenance, lug concentric butterfly valves with rubber seating can effectively control flow and provide reliable performance in marine applications and other industrial settingslet’s break down its features, considerations for selection, and how it’s typically used:

features:

concentric design: like other concentric butterfly valves, this type features a design where the stem passes through the center of the disc, ensuring a uniform seal around the circumference

selection considerations:

size and pressure rating: choose a valve size and pressure rating suitable for the intended application and operating conditionsrubber seats offer resilience, chemical resistance, and longevity, making them suitable for various fluids and operating conditions

rubber seating: the valve has rubber or elastomeric seating, typically made from materials like epdm or nbr, which provide excellent sealing propertiesconsider factors such as flow rate, system pressure, and compatibility with existing piping

material construction: select valve materials compatible with the fluid being handled and the environmental conditionstemperature, viscosity, chemical compatibility) and sealing requirementsmanual valves are operated by hand, while actuated valves can be controlled remotely using pneumatic, electric, or hydraulic actuators for automated flow controlcommon materials include stainless steel, carbon steel, ductile iron, and various alloys

emergency response: establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions

operation: operate the valve manually or remotely using the designated controls, following established procedures for opening, closing, and adjusting the flow as neededthis design minimizes turbulence and pressure drop while providing efficient flow control

lug style: the valve body has lugs (also known as ears or tabs) on the valve’s periphery, allowing it to be bolted directly between flanges in the pipeline

seat material: consider the type of seat material (ethis design provides easy installation and removal without needing to disconnect the entire pipeline

monitoring: periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazardsepdm, nbr, ptfe) based on the fluid properties (e

standards compliance: ensure the selected valve complies with relevant industry standards and certifications for quality, performance, and safety, such as ansi, api, iso, and marine classification societies’ requirements

operation type: decide whether manual or actuated operation is preferred based on the level of automation required, accessibility, and control system integration

maintenance: implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and longevityIndia

₹ 13827

-

Is a professional marine valve manufacturer, including butterfly valve, check valve, gate /knife gate valve

below is our wafer butterfly valve of marine valves,if you need to check more information, please click here:https://www

scope of application

marine butterfly valve is widely used in coal chemical industry, petrochemical industry, rubber, paper making, pharmaceutical and other pipelines as the medium of the shunt confluence or flow switching deviceproduct introduction

marine butterfly valve adopts the mounted structure, which reduces the connection bolts of the valve body itself under the condition of high pressure and large diameter, enhances the reliability of the valve and can overcome the influence of system weight on the normal work of the valve

we are committed to “build a top valve enterprise; be a reliable partner!”

friends from all over the world are welcome to visit us for evaluation, guidance, and orders!com/wafer-type-butterfly-valve-th-btv-aw/now we have our own independent r & d, manufacturing, assembly and warehousing workshops; we have professional pre-sale and after-sale technical support and perfect services

please contact us if you need more support, please contact us freely: info@tanghaivalve

tianjin tanghai valve cowe have certificates: ce, iso, bv, dnv foundry and products approvalIndia

₹ 1

-

butterfly table tennis blade is a famous brand for ping pong gearpeople like butterfly because they have cool designs and their things work wellmany professional players use butterfly products, and it's a popular choice for anyone who loves playing ping pongthey make good quality rackets, balls, tables, and other stuff for playing ping pong

India

₹ 1000

-

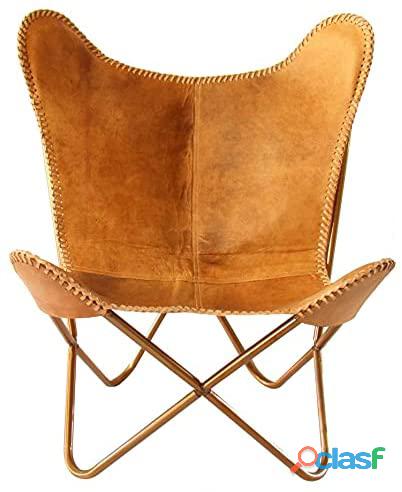

Get the top notch genuine leather butterfly chair at leather jacksonthis exemplary leather butterfly chair is made of genuine leather, is very strong and comes in all sizes

India

₹ 1

-

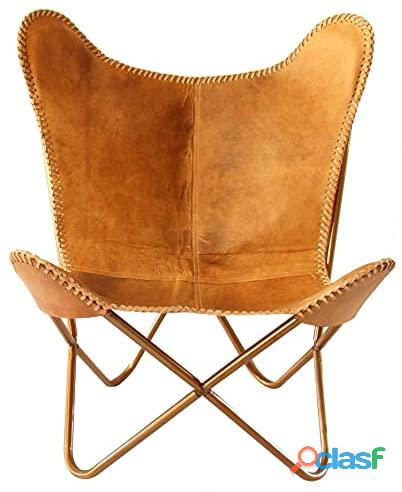

Get the excellent genuine leather butterfly chair at leather jacksonthis exemplary leather butterfly chair is made of genuine leather, is incredibly strong and comes in all sizes

India

₹ 1

-

butterfly fields - iit jee revision notes | concept map books by butterflyfields - asking price is ₹1057 for this books butterfly fields providing best revision tool for iit jee & morecovers all topics in math, physics and chemistry syllabus for iit, jee(mains)/bitsat, vitee, kcet, mhcet, emcet, tancet, mppet, iit & bord exams(new edition)helps in fast revision without getting distracted by unnecessary details

Faridabad New Township (Haryana)

₹ 1057

-

This beautiful and unique butterfly artwork is made by gluing 12it will add interest and brighten up any wall or cornerit can be great gift for a birthday, anniversary, house warming or just any occasionthis decorative piece uses a technique called quilling or paper filigreeto see more of my quilling art go here https://wwwin/user/profile/157521 contact 7990609093 aadhicreation2233@gmailthis exquisite piece is made with lots of love, happiness, hard work and patiencethe artwork is about 8"x10" and comes matted in a 11"x14" color white matit's ready to be framed in 11"x14" a deep frame or shadow box framekig10021height: 11 inches; width: 14 inchesit's a perfect gift for you or someone special who admires handmade artcomthank you for visiting and please come back soon to check out my new creations5 mm quilling paper strips to card stock paper in a design

Surat (Gujarat)

₹ 1499

-

It designs with cover closure, floral print butterfly pattern, and adjustable straptake this fashion crossbody bags for yourselfjust have it for yourselfu can team it up with tracksuits, dresses and sports clothes

India

-

Brand new box pack htc butterfly x920 with bill, 1yr wrnty and accessories @ rs1 mp secondary camera 8 mp primary camera expandable storage capacity of 32 gb full hd recording call @ (aditya)5 ghz qualcomm snapdragon s4 pro quad core processor 21 (jelly bean) os 5-inch super lcd 3 capacitive touchscreen (gorilla glass) 2 gb ram ddr3 16 gb onboard memory 25 gb of dropbox wi-fi enabled 1