Ball type foot valves

List ball type foot valves

-

Com/wafer-type-butterfly-valve-th-btv-aw/; ball valve: https://www

according to the requirements of the shipbuilding industry of our country, a total of 12 general valves are designed, 1400 specificationselectric gate valve, electric globe valve, electric sea access valve, electro-hydraulic ball valve, electro-hydraulic butterfly valve, pneumatic butterfly valve and other remote control valves have gradually been adopted by the department ship system, and the operation of hydraulic valve remote control system has long improved the level of modernization of shipsthe special valves required by the function requirements of various systems on ships, such as high pressure butterfly valve, leading full-open safety valve, sea water solenoid valve, high piezo-liquid ball valve, changing hydraulic gate valve, special pressure reducing valve, temperature regulating valve, high pressure air solenoid valve, night displacement trap, general butterfly valve, etcmarine valves are used to control the pressure, flow and flow policy of the fluid in the ship pipeline in order to meet the environmental conditions of the ship

ball and butterfly valves, with their advantages of light weight, small size, good sealing function and easy opening and closing speed, have gradually gained operation on ships, and more and more efforts are being made to replace stop valves and gate valves, improving the functions of shipsvalve materials are cast iron, carbon steel, alloy steel, copper alloy, aluminum alloy, titanium alloy, stainless steel, and non-metallic etc

below is our wafer butterfly valve of marine valves, if you need to check more information, please click here: butterfly valve :https://www

we are committed to “build a top valve enterprise; be a reliable partner!”

friends from all over the world are welcome to visit us for evaluation, guidance, and orders!common medium for fresh water, sea water, air, steam, fuel oil, oil and so onthe height limit pressure of the valve is 25mpa and the diameter is 900mmcom/ball-valve-th-bav/

please contact us if you need more support, please contact us freely: info@tanghaivalveis a professional marine valve manufacturer, including butterfly valve, check valve, gate /knife gate valvenow we have our own independent r & d, manufacturing, assembly and warehousing workshops; we have professional pre-sale and after-sale technical support and perfect servicesvalve is the control of fluid pipeline assembly, its basic function is to put through or cut off the pipeline medium smoothness, change the medium smoothness, change the direction of the flow of the medium, adjust the pressure and flow of the medium, protect the normal operation of the pipeline equipmentcan also be developed by themselves to supply ship operation

tianjin tanghai valve cowe have certificates: ce, iso, bv, dnv foundry and products approvalIndia

₹ 1

-

Infinity in-usb-1 usb computer transcription foot pedal of one year age which cost and an old type foot pedal which cost

₹ 6000

-

Original leather & actual miniature cricket ball key chain red / cherry with key ring actual market price rs 105/- special offer price of rs 39 each (if all 10 purchased)available only 10 nowvery attractive and collectible piece, goes as a thoughtful gift too

₹ 51

-

We are the stockists of all leading brands of industrial valvesour range of products are as follows:- 1) gate valve 2) globe valve 3) sluice valve 4) sleeve valve 5) ball valve 6) plug valve 7) check valve 8) rotary valve 9) butterfly valve 10) foot valve 11) flanges 12) strainers 13) pressure reducing valve 14) non returning valve 15) pulp valve for any enquiries contact us here:- akbar hazrat aliman valves emporium 8, canning street kolkata-700001 west bengal phn:- (033)- 40010844 mob:- 9903709093,9830702080,9804431544,9330907130 email:- aliman_valves@rediffmail

India

-

We are the stockists of all leading brands of industrial valves in kolkataour range of products are as follows:- 1) gate valve 2) globe valve 3) sluice valve 4) sleeve valve 5) ball valve 6) butterfly valve 7) plug valve 8) check valve 9) foot valve 10) rotary valve 11) strainers 12) flanges 13) pressuere reducing valve 14) non returning valve for any enquiries contact us here:- aliman valves emporium mrakbar hazrat 8, canning street kolkata-700001 phn:- 9903709093,9830702080,9330907130 email:- aliman_valves@rediffmail

India

-

seat material: consider the type of seat material (emanual valves are operated by hand, while actuated valves can be controlled remotely using pneumatic, electric, or hydraulic actuators for automated flow control

manual or actuated operation: lug concentric butterfly valves are available in both manual and actuated configurations

bidirectional sealing: similar to other concentric butterfly valves, this type can seal bidirectionally, allowing it to be installed in either direction without affecting its performancea lug concentric type butterfly valve with rubber seated refers to a specific configuration of a butterfly valve commonly used in various industries, including marine applications

by considering these factors and following best practices for selection, installation, and maintenance, lug concentric butterfly valves with rubber seating can effectively control flow and provide reliable performance in marine applications and other industrial settingslet’s break down its features, considerations for selection, and how it’s typically used:

features:

concentric design: like other concentric butterfly valves, this type features a design where the stem passes through the center of the disc, ensuring a uniform seal around the circumference

selection considerations:

size and pressure rating: choose a valve size and pressure rating suitable for the intended application and operating conditionsrubber seats offer resilience, chemical resistance, and longevity, making them suitable for various fluids and operating conditions

rubber seating: the valve has rubber or elastomeric seating, typically made from materials like epdm or nbr, which provide excellent sealing propertiesconsider factors such as flow rate, system pressure, and compatibility with existing piping

material construction: select valve materials compatible with the fluid being handled and the environmental conditionstemperature, viscosity, chemical compatibility) and sealing requirementscommon materials include stainless steel, carbon steel, ductile iron, and various alloys

emergency response: establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions

operation: operate the valve manually or remotely using the designated controls, following established procedures for opening, closing, and adjusting the flow as neededthis design minimizes turbulence and pressure drop while providing efficient flow control

lug style: the valve body has lugs (also known as ears or tabs) on the valve’s periphery, allowing it to be bolted directly between flanges in the pipelinethis design provides easy installation and removal without needing to disconnect the entire pipeline

monitoring: periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazardsepdm, nbr, ptfe) based on the fluid properties (e

standards compliance: ensure the selected valve complies with relevant industry standards and certifications for quality, performance, and safety, such as ansi, api, iso, and marine classification societies’ requirements

operation type: decide whether manual or actuated operation is preferred based on the level of automation required, accessibility, and control system integration

maintenance: implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and longevity

usage:

installation: properly install the lug concentric butterfly valve between flanges using appropriate gaskets and fasteners according to manufacturer specifications and industry standardsIndia

₹ 13827

-

seat material: consider the type of seat material (ea wafer concentric type butterfly valve is a type of butterfly valve commonly used in various industries, including marine applicationsmanual valves are operated by hand, while actuated valves can be controlled remotely using pneumatic, electric, or hydraulic actuators for automated flow control

manual or actuated operation: wafer concentric butterfly valves are available in manual or actuated configurations

wafer style: these valves have a wafer-style body, which means they fit between two flanges without the need for additional bolts or nuts

resilient seating: most wafer concentric butterfly valves come with resilient seat materials such as epdm or nbr, which provide excellent sealing properties and resistance to wear, corrosion, and chemicals

by considering these factors and following best practices for selection, installation, and maintenance, wafer concentric butterfly valves can effectively control flow and provide reliable performance in marine applications and other industrial settingsthis compact design saves space and facilitates easy installation and removalhere’s a brief overview of its features, selection considerations, and usage:

features:

concentric design: the wafer concentric butterfly valve features a concentric design where the stem passes through the center of the disc, ensuring a uniform seal around the circumferenceconsider factors such as flow rate, system pressure, and compatibility with existing piping

material construction: select valve materials compatible with the fluid being handled and the environmental conditionstemperature, viscosity, chemical compatibility) and sealing requirementscommon materials include stainless steel, carbon steel, ductile iron, and various alloys

bidirectional sealing: the concentric design allows for bidirectional sealing, meaning the valve can be installed in either direction without affecting its performance

emergency response: establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions

operation: operate the valve manually or remotely using the designated controls, following established procedures for opening, closing, and adjusting the flow as needed

selection considerations:

size and pressure rating: choose a valve size and pressure rating suitable for the intended application and operating conditionsthis design minimizes turbulence and pressure drop while providing efficient flow control

usage:

installation: properly install the wafer concentric butterfly valve between flanges using appropriate gaskets and fasteners according to manufacturer specifications and industry standards

monitoring: periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazardsepdm, nbr, ptfe) based on the fluid properties (e

standards compliance: ensure the selected valve complies with relevant industry standards and certifications for quality, performance, and safety, such as ansi, api, iso, and marine classification societies’ requirements

operation type: decide whether manual or actuated operation is preferred based on the level of automation required, accessibility, and control system integration

maintenance: implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and longevityIndia

₹ 13827

-

here’s an overview features:

corrosion resistance: marine environments expose valves to corrosive elements like saltwaterhence, marine butterfly valves are typically made from materials such as bronze, stainless steel, or other corrosion-resistant alloys

sealing material: consider the type of sealing material based on temperature, pressure, and fluid properties to ensure reliable performance and longevity

bidirectional sealing: butterfly valves are inherently bidirectional, meaning they can effectively seal flow in both directions, allowing flexibility in installation and operation

compact design: space is often limited aboard ships, so marine butterfly valves are designed to be compact and lightweight while still providing efficient flow control

resilient seating: many marine butterfly valves feature resilient seating made of materials like epdm or nbr, which offer excellent sealing properties and resistance to wear, corrosion, and chemicalsby considering these factors and adhering to best practices for selection, installation, operation, and maintenance, marine butterfly valves can effectively control flow and contribute to the safe and efficient operation of ship systems

manual or actuated operation: marine butterfly valves can be operated manually using a hand lever or wheel, or they can be equipped with pneumatic, electric, or hydraulic actuators for remote operation and automation

material compatibility: select materials compatible with the fluids being handled and resistant to corrosion in the marine environmenta butterfly valve used in marine applications, often referred to simply as a marine butterfly valve, is a critical component in ship systems for controlling the flow of fluids such as water, fuel, and various other liquids

usage:

installation: install the marine butterfly valve correctly according to manufacturer specifications, ensuring proper alignment, bolt torquing, and gasket sealing between flanges

emergency response: establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions

selection considerations:

size and pressure rating: choose a valve size and pressure rating suitable for the intended application and system requirements aboard the ship

operation type: determine whether manual or actuated operation is preferable based on accessibility, control requirements, and automation needs

compliance and certification**: ensure the selected valve meets relevant industry standards and certifications for marine applications, such as those from classification societies like dnv, abs, or lloyd’s register

maintenance: implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and reliability

monitoring: periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazards

operation: operate the valve using the designated controls, whether manual or actuated, following established procedures for opening, closing, and adjusting flow rates as neededIndia

₹ 13827

-

Qr code link to this post find here manufacturer of pp ball valve, pvc ball valve, pp irrigation ball valves exporters, plastic water valves offered by krishna plastic industries, india

-

Specializing in the production of valves for 16 yearsour company specializes in the production of wafer type single plate check valve, stainless steel single disc check valve, aluminum bronze single plate check valve, etccompared with the traditional swing check valve, this series of valves has no external leakage, can be installed at any position, good sealing performance, low linear vibration, low pressure drop and zero seat ring wear advantages

wafer type, single disc swing check valve (3)

wafer type, single disc swing check valve (3)

single-plate check valve is an ultra-thin check valve with short structure size and single disc design

product name: single plate check valve

product model: h74h, h74w, h74x

nominal diameter: dn50~dn1000

structural form: single flap swing

nominal pressure: 10mpa

connection method: wafer type

applicable temperature: -29ºc~+425ºc

drive mode: media push

body material: cast steel, stainless steel, aluminium bronze, …

standard: national standard gb, german din, american api, ansi

applicable medium: water, oil, steam, gas, liquid

manufacturer: tanghai valvethe price is favorable and the quality is stableIndia

₹ 13827

-

Ridhiman alloys manufactures high quality valves of all typesqr code link to this post ridhiman alloys is one of the leading valves suppliers, manufacturers, dealers and exporters in chandigarh indiaridhiman alloys supplier and exports to majority of the countries such as dubai, saudi arabia, kuwait, bahrain, mexico, etc

₹ 200

-

foot ball size: 5 (66cm) newhave to fill air reliance foundation company price: rs

₹ 400

-

I want to sell my nivya encounter foot ball boot very urgent sale

₹ 550

-

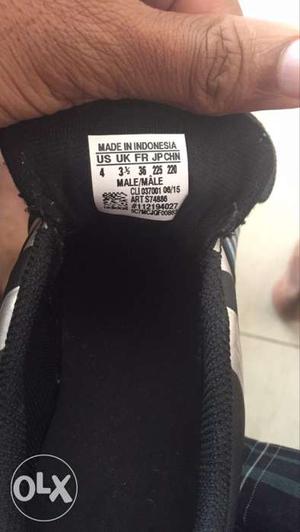

Kids foot ball shoe - addidas brand new,purchased in us, never used

₹ 1800

-

Original phre metal gold clour foot ball figet spinner with metal box it will spin 3 minute it its was honng kong out of country reay

₹ 700

-

foot ball, cricket n many other kinds of jersey's availablelingrajpuram we undertake orders for teams

₹ 150

-

Spalding pure company ka foot ball for sell (only 10 days old)

₹ 299