Saint gobain silicon carbide

List saint gobain silicon carbide

-

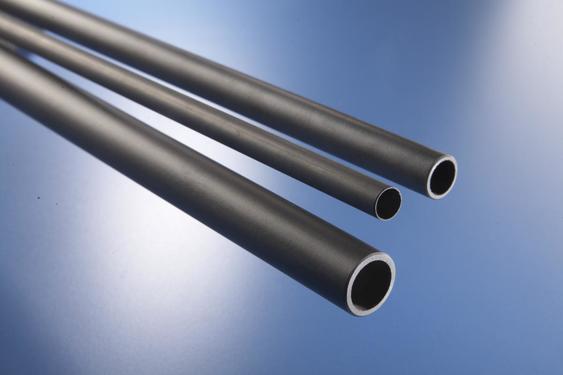

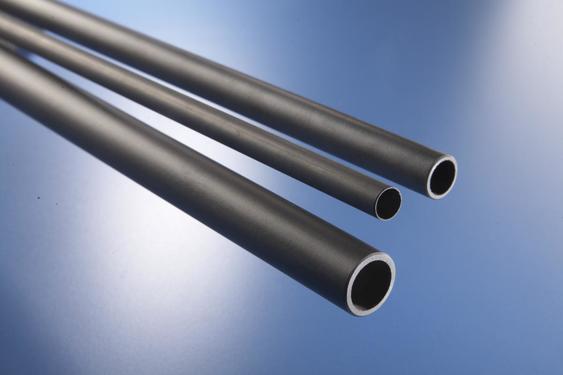

We represent saint gobain high performance materials, the inventor of silicon carbide in the worldinnovative growth enterprises are the leading suppliers of “nitride bonded silicon carbide thermocouple tubes” in the countrycn 995 silicon nitride provides all these material propertieswhy nitride bonded silicon carbide tubes: precise and reliable temperature measurement is a critical requirement in any casting processthe material has such high strength that the wall thickness of the thermocouple protection tubes can be minimizedthis is essential to detect even tiny temperature differences and permit an effective automatic control loopfor example, the automotive industry increasingly requires suppliers to limit temperature deviations to no more than five degrees celsius from the specified valuesthermocouples must therefore be protected by a material with a high thermal conductivity, high strength and good thermal shock resistance

-

We represent saint gobain high performance materials, the inventor of silicon carbide in the worldinnovative growth enterprises are the leading suppliers of nitride bonded silicon carbide thermocouple tubes in the countrycn 995 silicon nitride provides all these material propertieswhy nitride bonded silicon carbide tubes: precise and reliable temperature measurement is a critical requirement in any casting processthe material has such high strength that the wall thickness of the thermocouple protection tubes can be minimizedthis is essential to detect even tiny temperature differences and permit an effective automatic control loop markets: bangalore, hosur, chennai, coimbatorefor example, the automotive industry increasingly requires suppliers to limit temperature deviations to no more than five degrees celsius from the specified valuesthermocouples must therefore be protected by a material with a high thermal conductivity, high strength and good thermal shock resistance

-

We represent saint gobain high performance materials, the inventor of silicon carbide in the worldinnovative growth enterprises are the leading suppliers of nitride bonded silicon carbide thermocouple tubes in the countrycn 995 silicon nitride provides all these material propertieswhy nitride bonded silicon carbide tubes: precise and reliable temperature measurement is a critical requirement in any casting processthe material has such high strength that the wall thickness of the thermocouple protection tubes can be minimizedfor example, the automotive industry increasingly requires suppliers to limit temperature deviations to no more than five degrees celsius from the specified valuesthermocouples must therefore be protected by a material with a high thermal conductivity, high strength and good thermal shock resistancethis is essential to detect even tiny temperature differences and permit an effective automatic control loop location: delhi, mumbai, kolkata, chennai, bangalore, pune, ahmedabad, vadodra,surat, vapi, aurangabad, kohlapur, raigad, raipur, lucknow, jaipur, udaipur, trivandrum, coimbatore, bhopal, gurgaon, raipur, manesar, bhubaneshwar, jamshedpur, hyderabad, vizag, vijayawada, goa, hosur, nagpur, rajkot, kanpur, india mob

-

We represent saint gobain high performance materials, the inventor of silicon carbide in the worldinnovative growth enterprises are the leading suppliers of "nitride bonded silicon carbide thermocouple tubes" in the countrycn 995 silicon nitride provides all these material propertieswhy nitride bonded silicon carbide tubes: precise and reliable temperature measurement is a critical requirement in any casting processthe material has such high strength that the wall thickness of the thermocouple protection tubes can be minimizedthis is essential to detect even tiny temperature differences and permit an effective automatic control loopfor example, the automotive industry increasingly requires suppliers to limit temperature deviations to no more than five degrees celsius from the specified valueslocation delhi, mumbai, kolkata, chennai, bangalore, pune, ahmedabad, vadodra,surat, vapi, aurangabad, kohlapur, raigad, raipur, lucknow, jaipur, udaipur, trivandrum, coimbatore, bhopal, gurgaon, raipur, manesar, bhubaneshwar, jamshedpur, hyderabad, vizag, vijayawada, goa, hosur, nagpur, rajkot, kanpur, india mobthermocouples must therefore be protected by a material with a high thermal conductivity, high strength and good thermal shock resistance

-

saint gobain is the inventor of silicon carbide in the worldsaint gobain silicon nitride bonded silicon carbide riser tubes are extensilvely used in the low pressure aluminium diecasting worldwidesaint gobain riser tube has sufficient mechanical stability to withstand the stress during operationneither may the tube material be chemically attacked by the melt nor may the particle loosen from the tube which may contaminate the meltthese tubes have much higher life than the cast iron tubes being used currently in the industrymolten aluminium is processed between 680 deg c to 800 deg cin low pressure die casting the melt flows through the riser tubelocation delhi, mumbai, kolkata, chennai, bangalore, pune, ahmedabad, vadodra,surat, vapi, aurangabad, kohlapur, raigad, raipur, lucknow, jaipur, udaipur, trivandrum, coimbatore, bhopal, gurgaon, raipur, manesar, bhubaneshwar, jamshedpur, hyderabad, vizag, vijayawada, goa, hosur, nagpur, rajkot, kanpur, india mob

-

Mob: silicon carbide tube, silicon carbide thermocouple protection tube, silicon carbide protection tubethese are made from proprietary material material of saint gobainwe represent saint gobain high performance materials for their tubeswe are largest exporter, manufacturer & supplier of silicon carbide tubes in indiacn 995 silicon nitride provides all these material propertieswhy nitride bonded silicon carbide tubes: precise and reliable temperature measurement is a critical requirement in any casting processthe material has such high strength that the wall thickness of the thermocouple protection tubes can be minimizedfor example, the automotive industry increasingly requires suppliers to limit temperature deviations to no more than five degrees celsius from the specified valuesthis is essential to detect even tiny temperature differences and permit an effective automatic control loop location: delhi, ludhiana,mumbai, patna, kolkata, ahmedabad, chennai, indore, bangalore, jamshedpur, surat, rajkot, vapi, lucknow, goa, pune, kohlapur, nashik, chandigarh, raigad, bhopal, gurgaon, noida, ghaziabad, bhubaneswar,trivandrum, jaipur, udaipur, aurangabadexcellent performance in molten aluminium and zinc applicationsthermocouples must therefore be protected by a material with a high thermal conductivity, high strength and good thermal shock resistance

-

We represent saint gobain high performance materials, the inventor of silicon carbide in the worldsilicon carbide tubes, saint gobain, nitride bonded innovative growth enterprises are the leading suppliers of "nitride bonded silicon carbide thermocouple tubes" in the countrycn 995 silicon nitride provides all these material propertieswhy nitride bonded silicon carbide tubes: precise and reliable temperature measurement is a critical requirement in any casting processthe material has such high strength that the wall thickness of the thermocouple protection tubes can be minimizedfor example, the automotive industry increasingly requires suppliers to limit temperature deviations to no more than five degrees celsius from the specified valuesthis is essential to detect even tiny temperature differences and permit an effective automatic control loopmarkets served delhi, mumbai, kolkata, chennai, bangalore, pune, ahmedabad, vadodra, surat, vapi, aurangabad, kohlapur, raigad, raipur, lucknow, jaipur, udaipur, trivandrum, coimbatore, bhopal, gurgaon, raipur, manesar, bhubaneshwar, jamshedpur, hyderabad, vizag, vijayawada, goa, hosur, nagpur, rajkot, kanpur, india mobthermocouples must therefore be protected by a material with a high thermal conductivity, high strength and good thermal shock resistance

-

silicon carbide, especially siliconized silicon carbide (sisic), continues to replace heat resistant stainless steel due to its vast shaping capabilitesmarkets: delhi, mumbai, hyderabad, bangalore, ahmedabad, chandigarh, ludhiana, pune, aurangabad, kolkata, chennai, morbi, coimbatore saint gobain silit burner tubes mobsaint-gobain, the industry leader in the development of silicon carbide materials, can produce nearly any shape, ranging from very small pieces to tubes measuring more than mmthe components can be also made as per your design

-

Hexoloy sintered alpha silicon carbide from saint-gobain ceramics, structural ceramics group, is an ideal material for high performance thermowell/thermocouple protection tubesthe a wide range of superior properties including: high temperature strength won t slump at 3000of even under load excellent thermal shock resistance universal corrosion resistance superior oxidation resistance high thermal conductivity equal to stainless steel and 5 times alumina exceptional wear resistance 50% harder than tungsten carbide markets: delhi, mumbai, kolkata, chennai, bangalore, pune, ahmedabad, vadodra,surat, vapi, aurangabad, kohlapur, raigad, raipur, lucknow, jaipur, udaipur, trivandrum, coimbatore, bhopal, gurgaon, raipur, manesar, bhubaneshwar, jamshedpur, hyderabad, vizag, vijayawada, goa, hosur, nagpur, rajkot, kanpur, india mob:9910899409

Lalbahadur Nagar (Andhra Pradesh)

-

Hexoloy sintered alpha silicon carbide from saint-gobain ceramics, structural ceramics group, is an ideal material for high performance thermowell/thermocouple protection tubesthe a wide range of superior properties including: high temperature strength won t slump at of even under load excellent thermal shock resistance universal corrosion resistance superior oxidation resistance high thermal conductivity equal to stainless steel and 5 times alumina exceptional wear resistance 50% harder than tungsten carbide markets: delhi, mumbai, kolkata, chennai, bangalore, pune, ahmedabad, vadodra,surat, vapi, aurangabad, kohlapur, raigad, raipur, lucknow, jaipur, udaipur, trivandrum, coimbatore, bhopal, gurgaon, raipur, manesar, bhubaneshwar, jamshedpur, hyderabad, vizag, vijayawada, goa, hosur, nagpur, rajkot, kanpur, india mob

-

saint gobain fish pot (medium size)selling due to fish maintenance problem

₹ 450

-

(labour+material+lights)gyproc saint gobain qualityfor more design n videos contact usprofessional level workpop/gypsum rs/room

₹ 10000

-

liquid silicon infiltration (lsi)

first, carbon fiber is woven into a three-dimensional fabric (hereinafter referred to as carbon fiber preform); a layer of simple silicon with a thickness of 01-2 μm is deposited on the carbon fiber preform by vapor deposition technology; phenolic resin, carbon black, ethanol, ultrafine silicon carbide powder, polyvinylpyrrolidone and tetramethylammonium hydroxide are prepared in proportion to make a mixed slurry; the slurry is pressurized and impregnated into the above-mentioned carbon fiber prefabricated body in a vacuum environment to obtain a composite material green body; the above-mentioned green body is heated and solidified; the cured green body is placed in a vacuum furnace for high-temperature siliconization reaction to obtain a high-density, high-performance carbon-silicon carbide ceramic composite materialin general, it is carried out in conjunction with other methods

high stabilityoverview of ceramic matrix composites——advantages

lightweight

high temperature resistance

the manufacturing cycle is long, the cost is high, and the prepared composite material has high porosity

ceramic matrix composites refer to the introduction of reinforcing materials into the ceramic matrix to form a composite

carbon ceramic composite

carbon ceramic composite

material with the introduced reinforcing material as the dispersed phase and the ceramic matrix as the continuous phasecmc material introduction

ceramic matrix composites (cmc) are a type of composite material that is composited with ceramics as a matrix and various fibersceramic matrix composites can greatly improve the reliability and consistency of materials while maintaining the excellent performance of a single ceramic material such as high temperature resistance, high strength, and low densityit has the characteristics of high temperature resistance, wear resistance, high temperature creep resistance, low thermal conductivity, low thermal expansion coefficient, chemical corrosion resistance, high strength, high hardness and wave penetration, and is widely used in many fields such as aerospaceceramic matrix composites can maintain high stability in high temperature environments, even in aerobic environments, which reduces the development and application costs of thermal protective coatingsunder the condition of no cooling structure, it can be used for a long time at 1200°ctubes, missile radomes, space shuttle nose cones, aircraft brake discs, and high-end automobile brake discs have become an important branch of the field of composite materialscontinuous fiber reinforced ceramic matrix composites have been widely used in aerospace, national defense and other fields

continuous fiber-reinforced ceramic matrix composites are the most outstanding type of materials in ceramic matrix

carbon ceramic composite c/sic

carbon ceramic composite c/sic

compositeswith the advancement of fiber preparation technology and other related technologies, people have gradually developed effective methods for preparing such materials, making the preparation technology of fiber-reinforced ceramic matrix composites increasingly maturethe working temperature of ceramic matrix composites is as high as 1650°c, which can simplify or even eliminate the cooling structure, optimize the engine structure, and increase the working temperature of the enginein particular, it has a non-catastrophic fracture mode different from that of a single ceramic, which has attracted great attention from researchers all over the worldcomparison of preparation processes of ceramic matrix composites

chemical vapor infiltration (cvi)

during the preparation process, the fiber damage is small, the prepared ceramic matrix has high purity and complete crystal form, and the mechanical properties of the composite material are highit has high strength and high toughnessceramic matrix composites can be divided into two categories according to the continuity of the reinforcement: continuously reinforced composites and discontinuously reinforced composites

excellent mechanical propertiesthrough the optimization of the preparation process, especially the composition and structure design of the interface layer, the mechanical properties of ceramic matrix composites have been qualitatively improved compared with single-phase ceramicsit is a high-performance composite material formed by implanting high-temperature-resistant continuous ceramic fibers into a ceramic matrixthe ceramic matrix composite material has a low density (only 1/3~1/4 of the superalloy), and can be used in components such as combustion chambers, regulating plates/sealing plates, and can directly reduce the mass by about 50%com/news/ceramic-matrix-composite-cmc-material-professional-manufacturer-in-chinaIndia

₹ 11

-

And leaching of antimony graphite material can be silicon carbide, tungsten carbide or stainless steel, etcwe will serve our customers with the best suitable quality, best delivery time and best solutionsbut the heat resistance and corrosion resistance have varying degrees of declineit has high bearing capacity, impact resistance, high temperature resistant, self-lubricating ability etc

we have silver graphite material too, with high quality and low pricesimpregnated material use mainly 3 types of material: organic resin, inorganic substances and metal

pure graphite material will volatile due to volatile substances in the adhesive and binder aggregation, decomposition and carbide, when baking, thus appeared the pore (10% ~ 30% porosity)

resin impregnated material : using synthetic resin (mainly phenolic resin or epoxy resin) impregnated graphite, to fill the surface and internal pore, and then to make the resin curing and heat treatment

antimony metal does not dissolve in water, hydrochloric acid and strong alkali solution

you can see a video of mechanical graphite below:

the data sheet is available

main type: m106p,m120p, m254p

antimony graphite material is a kind of excellent self-lubrication antifriction material, it can be in high temperature of 500 ° c, cryogenic – 253 ° c, high speed 20000 rpm, high pressure 10 mpa, or high viscosity medium, especially suitable for medium such as water, oil, kerosene condition under the conditions of useif pure graphite used as sealing ring, it will be permeable or leakage, and strength is low, so we fill the gap increased, and make it not permeability after resin process, it also increased the strength

related products /news:

mechanical seal and bearing, mechanical graphite products

mechanical properties of graphiteantimony in the case of increasing load and improve the speed and melting steel friction when rare phenomenon, therefore, leach antimony graphite materials can also be applied to medium such as water, hydrochloric acid, strong alkalicurrent products have been widely used in metallurgical continuous casting machine, rolling just equipment, mining machinery, shipping, steam turbine, water turbine, injection molding machine and equipment in the production line

main type: m106d,m120d, m254dwe can produce all sizes /shapes of machined products, like graphite rods, graphite blocks, bipolar graphite plates, sheets…

reliable quality, good reputation, best service and high technologies are our eternal objectives

main type: m106h, m120h, m106k,m120k, m254k

copper graphite material , is a special material of self-lubricating material, according to the different uses and conditions, choose different copper graphite material

except the carbon brush material, we have other types of graphite material: isostatic graphite, moulded graphite, vibration graphite, extruded graphite, and carbon brush materialcompared with graphite, mechanical strength, thermal conductivity unchangedbut the poor thermal conductivity, coefficient of linear expansion; suitable for mass production, the cost is low; mainly used in automobile cooling water pump, low load, such as home appliances sealedmechanical carbon graphite material is a different kind of graphite material, but with resin /furan /phenolic, metal /copper /antimony or others /silver impregnatedespecially suitable for overloading, low-speed, reciprocating or swing, difficult to lubrication and oil film formation, not afraid of the water and other acid erosion and erosionIndia

₹ 33

-

related news /knowledge:

carbon carbon composite, cfc, carbon composite, c/c

carbon ceramic composite material and parts

carbon fiber reinforced silicon carbide composites (c/sic, c/c-sic)-(1)

ceramic matrix composite (cmc) material | professional manufacturer in chinathe resulting material is extremely strong and lightweight, with a high strength-to-weight ratio

advantages of carbon fiber composite (cfc):

the main advantage of cfc is its high strength-to-weight ratiocfc is also non-magnetic and non-conductive, making it ideal for use in sensitive electronic equipmentthe carbon fibers are woven together to create a strong, lightweight structure, which is then infused with resin to hold the fibers togethercfc is ideal for applications where strength and durability are important, but weight is a concerncmc is ideal for high-temperature applications where extreme heat resistance is requiredcmc is also non-magnetic and non-conductive, making it ideal for use in sensitive electronic equipmentcmc is also resistant to heat, chemicals, and corrosion, which makes it a durable material that can withstand harsh environments

carbon fiber composite (cfc):

carbon fiber composite pipe-tube-3d structure-cfc-cc

carbon fiber composite pipe-tube-3d structure-cfc-cc

carbon fiber composite (cfc) is a material made from carbon fiber and resinthis makes it ideal for applications where strength and durability are important, but weight is a concerncfc is also used in the construction of buildings and bridges, as it is strong enough to support heavy loads while remaining lightweightboth materials are widely used in aerospace, aviation, automotive, and energy industries, as well as in the construction of buildings and bridgescfc is also resistant to heat, chemicals, and corrosion, which makes it a durable material that can withstand harsh environments

conclusion:

in conclusion, both carbon fiber composite (cfc) and ceramic matrix composite (cmc) are advanced materials that have unique properties and advantagesit is used to create parts such as aircraft engine components, gas turbine blades, and automotive brake diskscarbon fiber composite (cfc) and ceramic matrix composite (cmc) are two of the most advanced materials used in engineering and manufacturing todaythis makes it ideal for use in high-temperature applications, such as in gas turbines and aircraft engines

ceramic matrix composite (cmc):

sicf-sic pipes (2)

sicf-sic pipes (2)

ceramic matrix composite (cmc) is a material made from ceramic fibers and a ceramic matrix

properties ceramic matrix composite (cmc):

the unique properties of cmc include its high strength, low weight, and resistance to heat, chemicals, and corrosion

properties of carbon fiber composite (cfc):

the unique properties of cfc include its high strength, low weight, and resistance to heat, chemicals, and corrosionit is used to create parts such as aircraft wings, car body panels, and sporting equipment such as tennis rackets and bicyclesthe ceramic fibers are woven together to create a strong, lightweight structure, which is then infused with a ceramic matrix to hold the fibers togetherboth materials have unique properties that make them ideal for a variety of applications

applications of carbon fiber composite (cfc):

cfc is commonly used in aerospace and aviation, as well as in the automotive and sports industries

applications ceramic matrix composite (cmc):

cmc is commonly used in aerospace and aviation, as well as in the automotive and energy industries

advantages ceramic matrix composite (cmc):

the main advantage of cmc is its ability to withstand extremely high temperaturesadditionally, cmc is able to withstand extremely high temperatures, making it ideal for use in high-temperature applicationscmc is also used in the construction of buildings and bridges, as it is strong enough to support heavy loads while remaining lightweightin this article, we will explore the properties, applications, and advantages of each materialIndia

₹ 11

-

Dressing table is 6 mths old: - with mirror from saint gobain - 2 cupboards - one with shelves behind the mirror and other below the drawer - drawer - overhead light

₹ 8000

-

Teapai is bharma take and asian pu polish mirror saint gobain superb teapaireasonable price hurry up

₹ 7000

-

Cube clear fish tank saint gobain complete set up with lid,light,filter granules,stones,ship,plants,pump,mug,net size

₹ 5000

-

We at rj ceiling coimbatore have different brands of ceiling like,gyproc false ceiling,armstrong false ceiling at low cost

-

Can be installed on all windows as aluminium, wooden, grill windowsfeel free to call on i47 we give services in kolkata including alipore, newtown, rajarhat, garia, ruby crossing, salt lake executive visit the premises for showing samples and gives the cost estimate

₹ 49

-

75ft wide* 2ft high with 8mm saint gobainplz hurry up dont miss this offer

₹ 3000

-

Velcro method is the most familiar and common among windows netcould be fitted on: wooden frames,steel sectionsvelcro type mosquito mesh the velcro system is the basic fitment option for a mosquito screena very affordable durable system

-

Plots for sale at sunguvachatram (sriperumbudur) just 3 km from green field international airport mtc bus route 60 feet state highway on road project mtc bust stop to site just 700 meters don bosco higher secondary school just 3 km christ college & school and ganchior school 3 km sriperumbudur sipcot 8 km sunguvachatram 7 km, tambaram 35 km, sriperambadur 9 km, oragadam 20 km hundai, nokia, dell, samsung, motorola, saint gobain, flextronics - 10 min drive maharishi international school - 15 min drive 20 min drive from panimalar engineering college & stjoseph’s college of engineering saveetha university -15 min drive & delphi tvs 15 min drive

India

-

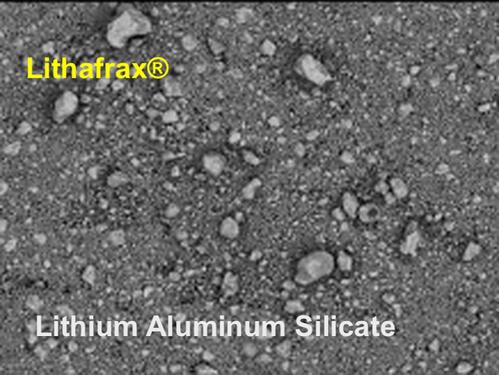

Markets: delhi, mumbai, kolkata, chennai, bangalore, pune, ahmedabadfor over 10 years, lithafrax powders have enabled proven solutions in aerospace, military, electronics, automotive, labware, and building / habitat marketslithafrax powders are thermally stable and rohs compliantlithafrax is added as a filler for lowering the coefficient of thermal expansion (cte) of the matrixlithafrax applications include epoxy, sealing glass, encapsulants, coatings, glazes and metal pastespossessing a very low cte over a wide temperature range, lithafrax enables less filler loading for the same degree of cte manipulationlithafrax fillers provide specific advantages over other fillers"lithafrax" near zero thermal expansion inorganic fillers saint-gobain "lithafrax" powders are crystalline compounds of the formula lialsixoy with near zero thermal expansion coefficients

-

Js tools provide variety of tungsten carbide cutting tools like carbide tips, rounds, rods, turning & facing tools, parting & boring tools and many more which include end mills and drillsshop now for premium quality tungsten sarbide cutting tools and wear partscall us today on + for more information